1. Introduction: Why Schedule Planning Decides Project Outcomes

Construction schedule planning strategies are now one of the biggest predictors of whether a project finishes on time, on budget, and with minimal disputes. Clients, lenders, and even regulators increasingly scrutinize programme logic, float consumption, and delay analysis before approving changes or extensions of time.

In 2026, rising material volatility, tighter margins, and complex supply chains mean that weak scheduling is no longer just an inconvenience; it is a direct financial risk. Teams that treat schedule planning as a box-ticking exercise tend to suffer cascading delays, inefficient resource use, and claims they struggle to substantiate.

This masterclass-style guide explains how to design, manage, and defend robust construction schedules using proven construction schedule planning strategies, combining traditional tools like Critical Path Method (CPM) with Lean techniques such as the Last Planner System and takt planning. Readers will find practical checklists, formulas, worked examples, and real project case studies to apply immediately on live projects.

Table of Contents

2. Why Schedule Planning Matters in Construction

Effective construction schedule planning strategies create a single source of truth for scope, sequence, and time risk, enabling better decisions from tender to handover. A well-structured baseline schedule helps coordinate design, procurement, construction, commissioning, and client approvals in one integrated plan.

Industry data shows that poor planning and scheduling are among the top causes of delay and cost overruns, often contributing to time extensions and disputes on large infrastructure and building projects. Studies on Lean and Last Planner implementation report notable improvements in planning reliability, with Percent Plan Complete (PPC) increases correlating to fewer disruptions and better predictability.

From an operational view, disciplined schedule planning allows:

- Proactive resource management so cranes, formwork, and key trades are available when needed instead of idle or double booked.

- Transparent communication with owners, consultants, and subcontractors, reducing surprises and building trust when adjustments are required.

Strategic schedule planning also supports contract administration and claims; logic-driven programmes with clear critical paths and documented updates form the backbone of forensic delay analysis.

3. Fundamental Concepts in Construction Scheduling

3.1 Activities, Work Breakdown Structure, and Coding

Construction schedules are built from discrete activities representing measurable work such as “Pour Level 3 slab” or “Install façade zone B.” A Work Breakdown Structure (WBS) groups these activities into logical levels (project → area → system → work package) so that planners, site teams, and management can view the project at varying detail.

Robust coding structures (WBS codes, cost codes, discipline codes, location codes) allow powerful filtering, grouping, and reporting, which is essential for earned value analysis and resource planning. When construction schedule planning strategies include consistent coding from tender through execution, teams avoid rework and fragmented data later.

3.2 Durations, Calendars, and Productivity

Activity durations are driven by quantities, crew productivity, and calendars. For example, if a team can install 100 m² of blockwork per day and the task is 1,000 m², the theoretical duration is 10 working days, adjusted for access, interfaces, and risk allowances.

Calendars define working days, shifts, holidays, and weather assumptions, and must match project reality (e.g., 6-day week for civil works, 5-day week for finishing trades). Good construction schedule planning strategies always differentiate calendars for site works, design, and approvals because non-site tasks often follow different patterns.

3.3 Relationships, Logic, and Critical Path

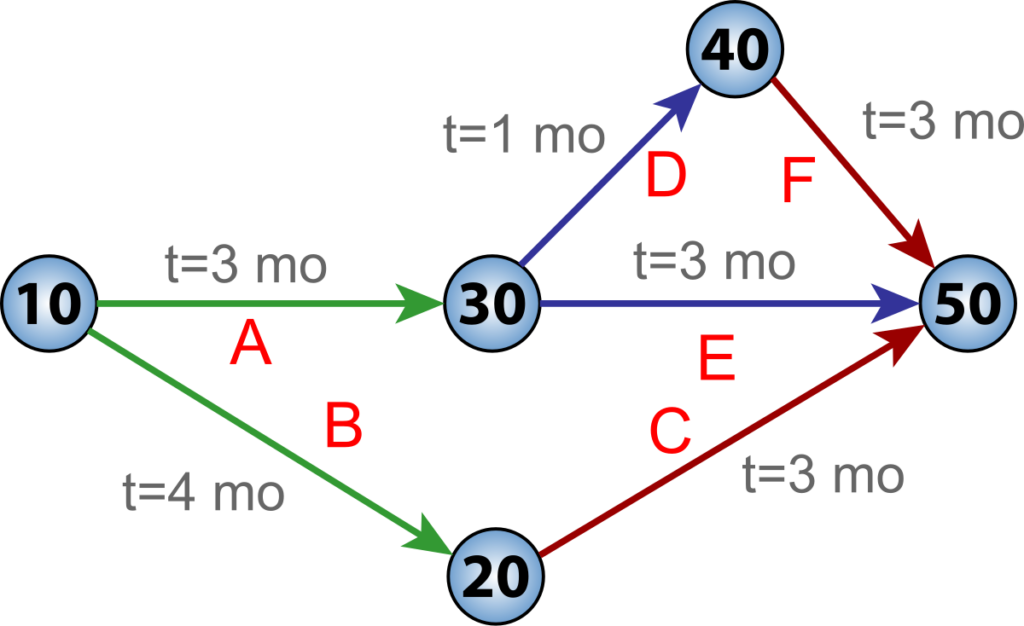

Schedule relationships (Finish-to-Start, Start-to-Start, etc.) represent the dependencies between tasks and determine the critical path—the longest path through the schedule that sets the minimum completion date. Critical activities have zero or minimal total float; delays here directly impact the project’s completion unless mitigated.

Strong schedule logic features:

Without logic-driven construction schedule planning strategies, the schedule becomes just a bar chart with no analytical value for risk or delay analysis.

3.4 Baseline, Updates, and Revisions

A baseline schedule is the formally approved time model used to measure performance and assess extensions of time. Regular updates compare actual progress versus baseline, adjusting remaining durations, status, and forecast completion dates.

Good practice includes periodic schedule health checks (e.g., number of activities without relationships, excessive float) and controlled revision processes when scope or strategy changes. Mature construction schedule planning strategies define clear rules for when a new baseline is needed versus when a normal update suffices.

4. Core Scheduling Methodologies and Techniques

4.1 Critical Path Method (CPM)

CPM remains the dominant method in construction schedule planning strategies for medium to large projects. It involves defining activities, durations, and relationships, then calculating early and late dates, float, and the project critical path.

CPM is well supported by tools like Primavera P6, MS Project, and cloud platforms, and is often contractually mandated in specifications and scheduling protocols. It provides a rigorous basis for claims and scenario analysis, particularly when combined with resource and cost loading.

Checklist: Setting up a CPM schedule

- Define WBS and coding structure.

- List all activities for design, procurement, construction, testing, and handover.

- Assign realistic durations based on data and productivity.

- Set calendars per trade and region.

- Link activities with logical predecessors and successors; avoid open ends.

- Run schedule calculation and review critical path, float, and logic gaps.

- Document assumptions and obtain formal baseline approval.

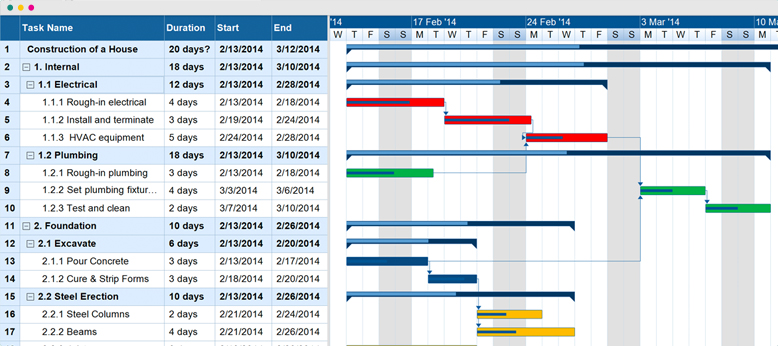

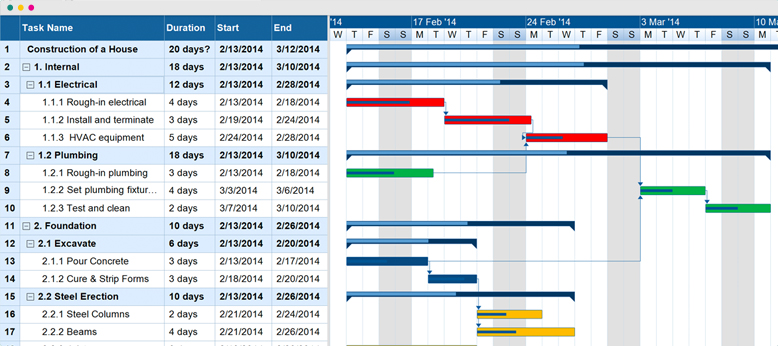

4.2 Gantt Charts and Milestone Planning

Gantt charts provide intuitive visual timelines and are widely used for communication with non-technical stakeholders. They can represent high-level phases and key milestones such as “Design freeze,” “Topping-out,” and “Substantial completion.”

While basic Gantt charts alone lack logic analysis, they become powerful when backed by CPM calculations and grouped by WBS, location, or trade. Many planners use simplified Gantt snapshots for client monthly reports while maintaining a more detailed CPM model behind the scenes as part of their construction schedule planning strategies.

4.3 Lean Construction and Last Planner System (LPS)

Lean construction aims to reduce waste and increase flow, with the Last Planner System at its core. LPS shifts planning responsibility towards the people closest to the work—foremen, superintendents, and trade leads—through collaborative weekly planning, constraint removal, and commitment-based scheduling.

Key components include:

- Pull planning workshops where teams sequence tasks backward from milestones.

- Weekly work plans built on what can be done (constraints removed), not just what should be done.

- Percent Plan Complete (PPC) tracking to measure how often weekly commitments are met and drive continuous improvement.

Studies show that implementing LPS often improves schedule reliability and reduces rework, making it a powerful complement to CPM-based construction schedule planning strategies.

4.4 Takt Planning and Location-Based Scheduling

Takt planning aligns work rhythms with a steady pace across locations, inspired by manufacturing. In construction, location-based scheduling and takt time approaches structure work so that crews flow from zone to zone with minimal waiting and interference.

This is particularly effective for repetitive projects such as residential towers, hotels, hospitals, and infrastructure segments where similar work repeats across floors or sections. When integrated with CPM and LPS, takt-based construction schedule planning strategies can shorten project durations and improve predictability.

5. Advanced Schedule Planning Applications

5.1 Integrated Design–Procurement–Construction Scheduling

Modern projects require integrating design, approvals, procurement, logistics, and construction into one coherent programme. Long-lead items such as façade systems, MEP equipment, and specialist finishes must be modelled from submittal to fabrication and delivery.

Advanced construction schedule planning strategies:

- Incorporate design deliverable schedules with clear issue-for-construction (IFC) dates aligned with site need dates.

- Model approval cycles, shop drawings, mock-ups, factory acceptance tests, and inspection windows to avoid on-site stoppages.

- Build material and equipment logistics into the schedule, especially for constrained urban sites or cross-border supply chains.

5.2 Risk-Based Planning and Schedule Contingency

Risk-based planning identifies threats and opportunities that could affect time, then quantifies them through techniques like Monte Carlo simulation or deterministic contingency allowances. Planners can add risk registers linked to schedule items, modelling potential delays in permits, utilities, or key trades.

This allows transparent contingency allocation and separate tracking of risk events versus normal productivity variances. In 2026, clients increasingly expect evidence-based contingency rather than arbitrary “padding,” making risk-based construction schedule planning strategies valuable during bids and negotiations.

5.3 Earned Value and Schedule Performance Metrics

Integrating cost and schedule enables earned value management (EVM), which measures performance using metrics such as Schedule Performance Index (SPI) and Cost Performance Index (CPI). Resource- or cost-loaded schedules allow calculation of planned value versus earned value per period, revealing whether the project is ahead or behind schedule in value terms.

Lean-based metrics like PPC from Last Planner complement these financial indicators by focusing on reliability of weekly planning. Combining EVM and PPC gives a richer picture of schedule performance and helps refine construction schedule planning strategies over time.

5.4 Digital Twins, BIM, and 4D Scheduling

4D scheduling links the time dimension to a 3D model, allowing teams to visualize how the project will be built over time. BIM-based 4D simulations help detect access clashes, temporary works conflicts, and logistical constraints that may not show clearly in bar charts.

Digital twin approaches extend this further by linking live sensor data, progress tracking, and facility management information to the schedule. Forward-looking construction schedule planning strategies harness these technologies to improve coordination, stakeholder understanding, and post-handover operations.

6. Tools & Software for Construction Scheduling in 2026

Construction schedule planning strategies rely on robust tools for modelling, updating, and communicating programmes. Common categories include:

- Enterprise-grade CPM tools such as Oracle Primavera P6 and similar platforms for complex multi-project portfolios.

- General project management tools like Microsoft Project, often used on small to mid-sized projects or by consultants for reporting.

- Cloud-based construction platforms (e.g., Procore, Autodesk Construction Cloud, Outbuild, SmartPM) that integrate scheduling with RFIs, submittals, and field management.

- Lean planning tools and digital whiteboards that support Last Planner, pull planning, and takt planning workflows.

Selection should align with the organisation’s construction schedule planning strategies, contractual obligations, and digital maturity, rather than tool popularity alone.

7. Worked Examples and Key Formulas

7.1 Basic Productivity-Based Duration Calculation (Worked Example 1)

Consider a blockwork package for a residential floor: 1,200 m² of internal blockwork, single crew, typical productivity of 80 m² per day based on past data.

The basic duration formula is:Duration (days)=Daily productivity×Number of crewsTotal quantity

Using the values:Duration=80×11,200=15 working days

If a 10% contingency is added for coordination and access issues, the planned duration becomes 17 days (rounded). Integrating this into construction schedule planning strategies ensures that durations have transparent assumptions that can be revisited if actual conditions differ.

7.2 Takt Time Planning for Repetitive Floors (Worked Example 2)

Assume a high-rise with 20 identical floors where structural, MEP rough-in, and finishes each require about 10 working days per floor, but cannot fully overlap due to access constraints. The client wants a steady handover of one floor every 6 working days.

The takt time formula is:Takt time=Required outputAvailable time

If the project has 120 working days to complete 20 floors, the takt time is:Takt time=20120=6 days per floor

Construction schedule planning strategies would then:

- Break each floor into zones.

- Align structural, MEP, and finishes crews so each moves to the next floor every 6 days, even if internal task durations differ slightly.

The result is a predictable production rhythm with less waiting and congestion, which has been shown in practice to reduce overall duration and labour variability.

8. Common Scheduling Mistakes and How to Fix Them

8.1 No Logic-Driven Baseline

Mistake: Baseline schedule built mainly as a bar chart with minimal logic or missing design/procurement.

Impact: Impossible to analyse critical path or justify delays; reactive fire-fighting.

Solution: Enforce construction schedule planning strategies that require complete logic (no open ends, realistic relationships) and integrated phases before approval.

8.2 Ignoring Procurement and Long-Lead Items

Mistake: Procurement modelled as a single activity or omitted entirely.

Impact: Late materials or equipment delay installation activities, with little visibility beforehand.

Solution: Build detailed procurement chains (submittal, review, fabrication, shipping, customs, delivery) and link them to site tasks.

8.3 Over-Optimistic Durations and Lack of Data

Mistake: Durations chosen by guesswork or pressure to “fit” contract dates.

Impact: Chronic slippage, low PPC, and demoralized teams when targets are constantly missed.

Solution: Use historical data, standard productivities, and risk-based allowances; track actuals to refine assumptions on future projects.

8.4 No Regular Updates or Health Checks

Mistake: Schedules updated irregularly or just before client reviews.

Impact: Poor visibility of developing delays and ineffective mitigation.

Solution: Define update cycles (e.g., weekly internal, monthly external) and standard health check criteria (logic errors, excessive float, out-of-sequence progress).

8.5 Weak Integration with Site Teams

Mistake: Planning done in isolation; site teams see the schedule only in reports.

Impact: Lack of ownership, frequent changes on site, and unreliable weekly plans.

Solution: Incorporate Last Planner practices where foremen contribute to lookahead and commit to weekly plans, supported by constraints removal.

9. Real-World Case Studies

9.1 Case Study 1: Commercial Tower with Last Planner Integration

A 40-storey commercial tower project adopted a hybrid of CPM-based master scheduling and Last Planner System at the field level. The initial baseline was prepared in Primavera with full design, procurement, structural, façade, and fit-out phases, including detailed long-lead façade procurement.

Weekly Last Planner meetings involved trade foremen who collaboratively developed 6-week lookahead plans and committed weekly work plans. PPC was tracked and root causes of non-completion were analysed, supporting a continuous improvement cycle that raised PPC from about 60% to over 80% during peak construction.

The combination of top-down CPM and bottom-up commitment planning reduced rework and improved coordination between core/structure and façade works, contributing to achieving substantial completion within a few days of the baseline completion date despite early procurement challenges.

9.2 Case Study 2: Infrastructure Project with Risk-Based Schedule

On a major roadway and bridge package, the owner required a risk-based schedule supported by quantitative analysis. The planning team developed a detailed CPM model and then performed schedule risk analysis, assigning probability distributions to key risks such as weather, utility diversions, and third-party approvals.

Simulation results showed a low probability of completion by the original contractual date without additional contingency. The team then proposed phased acceleration measures and negotiated a risk-adjusted completion date and contingency plan with the client, reducing the likelihood of dispute later.

During execution, periodic schedule updates and risk reviews enabled targeted mitigation, and the project ultimately finished within the agreed risk-adjusted time window.

9.3 Case Study 3: Residential Block Using Takt and Location-Based Planning

A residential complex with multiple identical blocks implemented location-based and takt planning to stabilize production of structure, MEP, and finishes. The planner divided each block into standardized zones and defined takt sequences so trades moved in a predictable rhythm across zones and floors.

Using these construction schedule planning strategies, the project reduced average cycle time per floor compared with previous similar projects and improved labour utilization due to reduced idle time and fewer trade clashes. Client handovers occurred in regular batches, improving cash flow and inspection scheduling.

10. Practical Checklists for Planners and Site Teams

10.1 Baseline Schedule Development Checklist

- Confirm contract milestones and liquidated damages triggers.

- Create WBS aligned with scope, areas, and systems.

- Include design, approvals, procurement, construction, testing, and handover.

- Assign realistic durations based on data; document assumptions.

- Apply appropriate calendars (site, design, supplier).

- Build complete logic, avoiding open ends and unnecessary date constraints.

- Review critical path and near-critical paths for feasibility.

- Obtain stakeholder review (project management, construction, key trades).

- Secure formal baseline approval with version control.

10.2 Weekly Planning and Last Planner Checklist

- Hold a weekly coordination meeting with all major trades.

- Review the 6-week lookahead to identify constraints (drawings, access, approvals, materials).

- Remove or mitigate constraints before work enters the weekly plan.

- Get explicit commitments from each trade for the coming week.

- Track PPC and record reasons for non-completion.

- Adjust future planning based on patterns in PPC and root causes.

10.3 Monthly Schedule Review and Health Check

- Update actual dates, progress percentages, and remaining durations.

- Recalculate schedule and compare forecast completion to baseline.

- Check for open ends, out-of-sequence progress, excessive lags, and high float.

- Review impact of delays on critical and near-critical paths.

- Coordinate with cost team to update earned value reports if cost loading exists.

- Prepare clear narratives and visual aids for client reports.

11. FAQ: Construction Schedule Planning & Strategies

Q1. What are construction schedule planning strategies?

Construction schedule planning strategies are structured approaches for defining, sequencing, and controlling project activities to deliver construction works within time and resource constraints, often combining CPM, Lean, Last Planner, and risk-based methods.

Q2. Which scheduling method is best for construction projects?

For most projects, CPM-based scheduling is the contractual backbone, supported by Lean tools like Last Planner for field-level planning and takt/location-based methods on repetitive projects. The best method is usually a hybrid tailored to project type and organisation capabilities.

Q3. How often should a construction schedule be updated?

Many organisations update schedules internally on a weekly basis and issue formal client updates monthly, though high-risk projects may require more frequent updates. The key is consistent cycles so that issues are detected early and mitigation can be implemented.

Q4. How can PPC and Lean metrics help improve scheduling?

Percent Plan Complete (PPC) measures how reliably weekly work plans are executed, and is a core metric in the Last Planner System. Tracking PPC and analysing reasons for non-completion drives continuous improvement in planning reliability and field coordination.

Q5. What role does BIM/4D play in schedule planning?

4D scheduling connects the CPM programme to a 3D model, enabling visual simulations of how the project will be built over time, which helps identify clashes, access issues, and sequencing problems before they occur. This visual clarity improves stakeholder understanding and coordination.

Q6. How should planners handle long-lead items in the schedule?

Planners should create detailed chains for long-lead items (submittals, approvals, fabrication, transport, customs, delivery) and link them logically to on-site installation activities. This allows proactive monitoring and earlier mitigation if delays occur.

Q7. Can schedule risk analysis really reduce delays?

Schedule risk analysis does not remove uncertainty, but it highlights where time risk is concentrated and tests the robustness of construction schedule planning strategies under different scenarios. Projects that act on these insights often have fewer surprises and more realistic completion forecasts.

Q8. What KPIs should be monitored for schedule performance?

Useful KPIs include PPC (for planning reliability), SPI from earned value analysis, number of activities on or near the critical path, and frequency of out-of-sequence progress. Together, these metrics offer both high-level and field-level insights.

12. Conclusion: Building Schedule Discipline in 2026

In 2026, construction schedule planning strategies are no longer optional; they are central to competitive advantage, claim defensibility, and project profitability. Clients expect transparent, logic-driven programmes that integrate design, procurement, and construction, backed by realistic durations and visible risk contingencies.

Teams that combine CPM with Lean tools like Last Planner, PPC measurement, and takt-based planning build more reliable workflows, reduce rework, and stabilise labour utilisation. Adding digital capabilities such as 4D scheduling and integrated construction platforms further enhances coordination and stakeholder communication.

For organisations willing to invest in training, data-driven planning, and collaborative culture, robust construction schedule planning strategies transform scheduling from a compliance task into a strategic capability. By applying the checklists, worked examples, and case insights in this guide, project teams can strengthen baselines, respond faster to disruptions, and consistently deliver on their time commitments.

13. Free Resources for Construction Planners

- Open articles on modern construction scheduling, Lean planning, and Last Planner implementation from professional bodies and industry platforms.

- Vendor knowledge bases from major scheduling and construction management software tools, which often include templates and how-to guides.

- Selected conference presentations and academic papers on Lean construction and schedule reliability, accessible via professional associations.