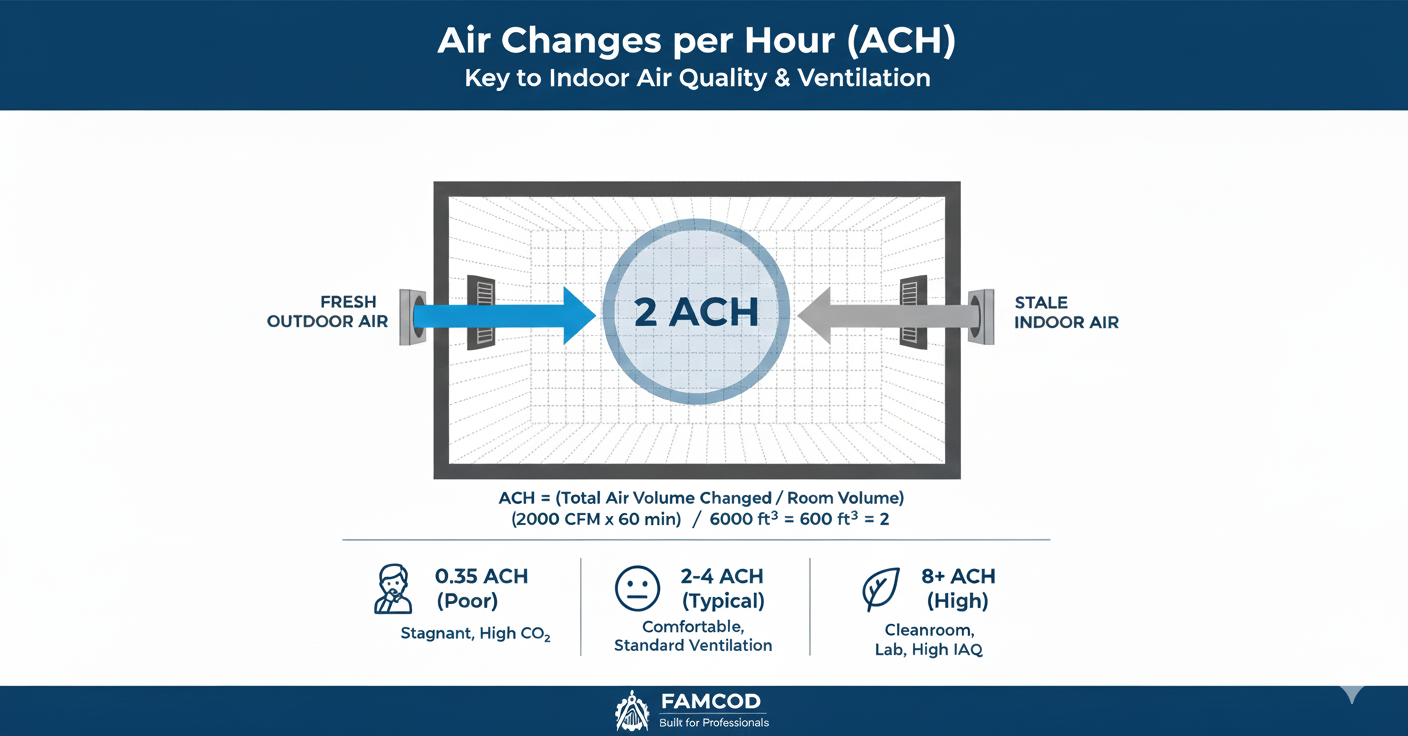

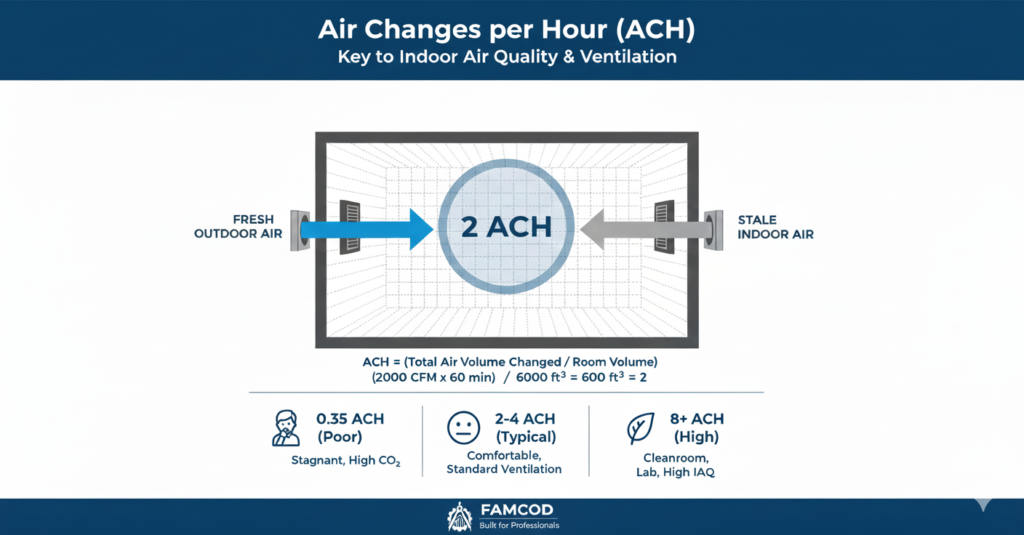

Understanding ACH: Air Changes per Hour is a fundamental metric in HVAC and indoor air quality (IAQ). It represents the number of times the entire volume of air within a space is replaced by fresh or filtered air in one hour.

Air Changes per Hour (ACH) is one of the most fundamental concepts in HVAC design and indoor air quality (IAQ) management. Whether you’re designing a residential home, a commercial office, a hospital, or a manufacturing facility, understanding how to calculate and apply ACH is critical for creating healthy, efficient, and compliant indoor environments.

This comprehensive guide breaks down every aspect of ACH calculations—from basic formulas to advanced applications in specialized buildings. By the end, you’ll have the knowledge to design ventilation systems that meet codes, optimize energy use, and protect occupant health.

What Is Air Changes per Hour (ACH)?

Air Changes per Hour (ACH) is a measurement that describes how many times the entire volume of air in a space is completely replaced with fresh air over a 60-minute period.

Definition & Units

- Definition: The number of times per hour that all the air in a space is replaced with fresh air

- Units: ACH (no dimension), or air changes per hour

- Symbol: n or ACH

- Range: Typically 0.5 ACH to 20+ ACH depending on building type

Simple Example

If a room has an ACH of 4, this means:

- All the air in the room is completely replaced 4 times per hour

- The air is replaced every 15 minutes (60 minutes ÷ 4 changes = 15 minutes)

- After 15 minutes, approximately 100% of the original air has been replaced

- After 5 minutes, approximately 63% of the original air has been replaced

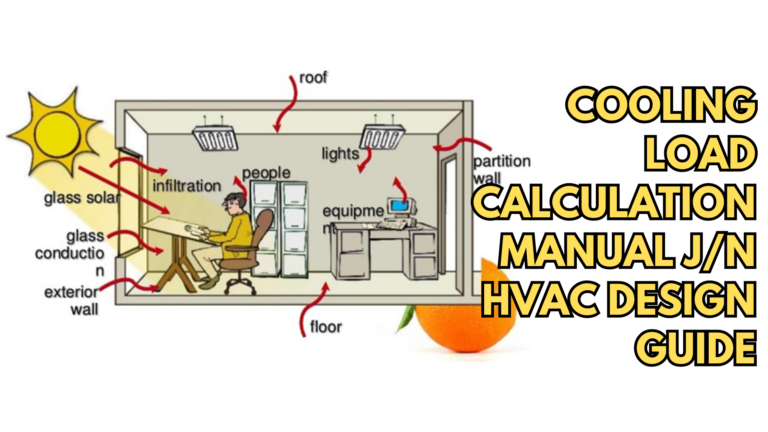

Visual Representation

In a 1,000 cubic foot room with 4 ACH:

- Ventilation rate = 4,000 cubic feet per hour (CFH)

- Ventilation rate = 67 cubic feet per minute (CFM)

- Complete air exchange occurs every 15 minutes

Why ACH Matters in HVAC Design

1. Indoor Air Quality (IAQ) Protection

Higher ACH rates dilute indoor pollutants and contaminants:

- Odors: Cooking smells, bathroom odors, chemical fumes

- CO₂: Carbon dioxide buildup from occupant respiration

- Volatile Organic Compounds (VOCs): Emissions from furniture, paints, cleaning products

- Particulates: Dust, pollen, PM2.5, PM10

- Pathogens: Virus transmission, bacteria, fungal spores

Example: Hospital operating rooms maintain 12–15 ACH to minimize airborne pathogen transmission during surgery.

2. Health & Wellness

Scientific research shows ACH directly impacts:

- Cognitive function: Higher ACH (6+ ACH) improves decision-making in offices

- Respiratory health: Adequate ACH reduces asthma/allergy symptoms

- Sleep quality: Optimal ACH (2–4 ACH) improves bedroom air quality

- Disease transmission: Higher ACH reduces airborne disease spread (COVID-19, influenza, tuberculosis)

Study Reference: A 2016 Harvard University study found office workers in buildings with higher ventilation rates (4.5+ ACH) had 101% higher cognitive scores.

3. Code Compliance

Building codes mandate minimum ACH rates:

- ASHRAE 62.1: Ventilation standard specifying CFM per person + CFM per square foot

- IECC: Energy code ventilation requirements

- IBC: International Building Code mechanical provisions

- Local codes: Jurisdiction-specific ventilation minimums

Failure to meet ACH codes can result in:

- Building rejection by health authorities

- HVAC system redesign (costly rework)

- Project delays

- Potential legal liability

4. Energy & Sustainability

ACH significantly impacts HVAC energy consumption:

- Higher ACH = Higher energy cost (more outside air requires conditioning)

- Lower ACH = Lower energy cost (but compromises IAQ)

- Optimal ACH = Balance between IAQ and energy efficiency

- Energy recovery: HRV/ERV systems reduce energy penalty of higher ACH

Example: Increasing ACH from 2 to 4 in an office building can increase annual HVAC energy costs by 20–30% without energy recovery equipment.

5. Moisture Control

Adequate ACH prevents moisture accumulation:

- High humidity: Inadequate ventilation traps moisture → mold growth, structural damage

- Low humidity: Excessive ventilation in dry climates dries indoor air → comfort issues

- Condensation: Inadequate ACH leads to condensation on windows/pipes

- Dehumidification: Higher ACH in humid climates removes moisture naturally

ACH Calculation Formula

Basic Formula

The fundamental ACH calculation is straightforward:ACH=Room Volume (cubic feet)CFM (Ventilation Rate)×60

Or rearranged:CFM=60ACH×Room Volume

Formula Breakdown

- CFM = Cubic Feet per Minute (ventilation rate)

- 60 = Conversion factor (minutes per hour)

- Room Volume = Length × Width × Height (in feet)

- ACH = Air Changes per Hour (desired result)

Example Calculation 1: Residential Bedroom

Given:

- Room dimensions: 12 ft × 14 ft × 9 ft ceiling

- Desired ACH: 3 (typical residential)

Step 1: Calculate room volume

Volume = 12 × 14 × 9 = 1,512 cubic feet

Step 2: Convert ACH to CFM

CFM = (3 ACH × 1,512 cu ft) ÷ 60 = 75.6 CFM

Step 3: Interpretation

A ventilation system delivering 76 CFM achieves 3 ACH in this bedroom, completely replacing the air every 20 minutes (60 ÷ 3).

Example Calculation 2: Commercial Office Space

Given:

- Office dimensions: 20 ft × 25 ft × 10 ft ceiling

- Number of occupants: 8 people

- Desired ACH: 2 (energy-efficient office)

Step 1: Calculate room volume

Volume = 20 × 25 × 10 = 5,000 cubic feet

Step 2: Convert ACH to CFM

CFM = (2 ACH × 5,000 cu ft) ÷ 60 = 166.7 CFM (rounded to 167 CFM)

Step 3: Alternative check using ASHRAE 62.1

ASHRAE 62.1 specifies:

- Office spaces: 15 CFM per person + 0.06 CFM per square foot

- Per person: 8 people × 15 CFM/person = 120 CFM

- Per area: (20 × 25 = 500 sq ft) × 0.06 = 30 CFM

- Total: 120 + 30 = 150 CFM

Comparison: ACH method = 167 CFM vs. ASHRAE method = 150 CFM

Use the higher value (167 CFM) to ensure code compliance.

Example Calculation 3: Retail Store

Given:

- Store floor area: 3,000 square feet

- Ceiling height: 12 feet

- ASHRAE 62.1 requirement: 0.30 CFM per square foot (retail standard)

Step 1: Calculate CFM using ASHRAE 62.1

CFM = 3,000 sq ft × 0.30 CFM/sq ft = 900 CFM

Step 2: Calculate room volume

Volume = 3,000 × 12 = 36,000 cubic feet

Step 3: Calculate ACH

ACH = (900 CFM × 60) ÷ 36,000 = 1.5 ACH

Interpretation: The ASHRAE 62.1 requirement translates to 1.5 ACH for this retail space.

ACH Standards by Building Type

Different building types require different ACH rates based on occupancy, activity, and health risks:

Residential Buildings (Homes & Apartments)

| Space Type | Typical ACH | Application |

|---|---|---|

| Bedrooms | 2–4 | Comfortable air quality, energy efficient |

| Living areas | 2–3 | General occupancy, moisture control |

| Kitchens | 4–6 | Odor & cooking fume removal |

| Bathrooms | 6–8 | Moisture & odor control |

| Basements | 2–4 | Humidity & mold prevention |

| Attics | 0.5–1 | Moisture removal, roof protection |

| General (whole house) | 0.6–1.2 | ASHRAE 62.2 minimum ventilation |

ASHRAE 62.2 (Residential): Minimum CFM = 0.03 × House area (sq ft) + 7.5 × Number of bedrooms

Example: 2,000 sq ft home with 4 bedrooms

CFM = (0.03 × 2,000) + (7.5 × 4) = 60 + 30 = 90 CFM

Commercial Buildings (Offices, Retail, Restaurants)

| Space Type | Typical ACH | Application |

|---|---|---|

| Private offices | 2–4 | General office work |

| Open-plan offices | 3–5 | Higher occupant density |

| Conference rooms | 2–4 | Meeting spaces |

| Retail stores | 1–2 | General shopping, low activity |

| Restaurants (dining) | 3–4 | Odor control, moisture |

| Restaurants (kitchen) | 8–15 | Heavy cooking fume removal |

| Restrooms | 6–10 | Odor & moisture removal |

| Stairwells | 2–4 | Escape route pressurization |

| Lobbies | 1–2 | Low activity, high ceilings |

| Corridors | 0.5–1 | Circulation spaces |

ASHRAE 62.1 (Commercial): Varies by space type and occupancy

Example: Office with 50 people in 2,500 sq ft

- Per person: 50 people × 15 CFM/person = 750 CFM

- Per area: 2,500 sq ft × 0.06 CFM/sq ft = 150 CFM

- Total: 750 + 150 = 900 CFM minimum

Healthcare Facilities (Hospitals, Clinics)

| Space Type | Typical ACH | Application |

|---|---|---|

| Patient rooms (isolation) | 6–12 | Infection control, negative pressure |

| Patient rooms (general) | 4–6 | Standard care |

| Operating rooms | 12–25 | Surgical environment, positive pressure |

| Recovery rooms | 4–6 | Post-operative care |

| ICU/CCU | 6–12 | Critical care isolation |

| Labs | 6–12 | Biohazard containment |

| Pharmacies | 4–6 | Contamination control |

| Restrooms | 8–10 | Odor control, negative pressure |

Standard: ASHRAE 170 Healthcare HVAC Design (specialized requirements)

Educational Facilities (Schools, Universities)

| Space Type | Typical ACH | Application |

|---|---|---|

| Classrooms | 3–5 | Student occupancy, CO₂ control |

| Lecture halls | 3–5 | Large occupancy |

| Laboratories | 6–10 | Chemical/fume control |

| Libraries | 2–3 | General occupancy |

| Cafeterias | 4–6 | Food prep, odor control |

| Gymnasiums | 3–5 | High activity, moisture control |

| Restrooms | 6–10 | Odor removal |

| Locker rooms | 4–6 | Moisture & odor control |

Industrial & Manufacturing

| Space Type | Typical ACH | Application |

|---|---|---|

| General factories | 2–4 | Dust/fume removal |

| Welding shops | 4–8 | Fume extraction |

| Painting booths | 6–15 | Solvent/overspray control |

| Electronics assembly | 4–6 | Static control, contamination |

| Food processing | 6–12 | Hygiene, odor control |

| Chemical plants | 8–20 | Hazardous gas control |

| Warehouses | 1–2 | Low occupancy, general storage |

Specialized Facilities

| Space Type | Typical ACH | Application |

|---|---|---|

| Clean rooms (ISO 5) | 50+ | Microelectronics, pharma manufacturing |

| Clean rooms (ISO 7) | 20–50 | Medical device assembly |

| Clean rooms (ISO 8) | 10–20 | General clean room |

| Data centers | 4–10 | Equipment cooling + air quality |

| Server rooms | 3–6 | Equipment protection |

| Museums/archives | 2–3 | Artifact preservation |

| Wine cellars | 1–2 | Temperature/humidity stability |

| Animal facilities | 6–15 | Odor/ammonia control |

| Pharmaceutical labs | 8–12 | Biohazard containment |

Step-by-Step ACH Calculation Guide

Method 1: ACH Formula (Simple)

Use this when you know the desired ACH and need to find CFM.

Step 1: Determine room dimensions

- Length: _____ ft

- Width: _____ ft

- Height: _____ ft

Step 2: Calculate room volume

Volume = Length × Width × Height = _____ cubic feet

Step 3: Determine desired ACH

- Check ASHRAE 62.1, 62.2, or local codes

- Reference table above

- Desired ACH = _____

Step 4: Calculate CFM

CFM = (ACH × Volume) ÷ 60 = _____ CFM

Step 5: Select HVAC equipment

- Choose blower/fan delivering calculated CFM

- Add 10% safety margin

- Design CFM = _____ CFM × 1.10 = _____ CFM

Method 2: ASHRAE 62.1 Standard (Commercial)

Use this when designing commercial spaces with code compliance required.

Step 1: Identify space type

Example: Private office

Step 2: Find ASHRAE 62.1 ventilation rate

- Per person (Rp): 15 CFM/person

- Per area (Ra): 0.06 CFM/square foot

Step 3: Count occupants

Number of people = _____

Step 4: Calculate room floor area

Area = Length × Width = _____ square feet

Step 5: Calculate ventilation rate

- CFM (per person) = Occupants × Rp = _____ × 15 = _____ CFM

- CFM (per area) = Area × Ra = _____ × 0.06 = _____ CFM

- Total CFM = Sum of both components = _____ CFM

Step 6: Calculate ACH (for reference)

Volume = Area × Ceiling height = _____ cubic feet

ACH = (Total CFM × 60) ÷ Volume = _____ ACH

Method 3: ASHRAE 62.2 Standard (Residential)

Use this for homes and apartments.

Step 1: Measure house floor area

Total conditioned area = _____ square feet

Step 2: Count bedrooms

Number of bedrooms = _____

Step 3: Calculate minimum ventilation CFM

CFM = (0.03 × Area) + (7.5 × Bedrooms)

CFM = (0.03 × _____) + (7.5 × _____) = _____ CFM

Step 4: Account for air leakage

- Tight house (new construction): ACH50 < 3

- Whole-house CFM = Calculated CFM

- Average house: ACH50 = 7

- Whole-house CFM = Calculated CFM × 0.85

- Leaky house (old): ACH50 > 10

- Whole-house CFM = Calculated CFM × 0.60

Step 5: Size ventilation fan

- Design CFM = Calculated CFM (with blower door adjustment)

Method 4: Custom Calculation (Specialized Spaces)

Use this for unique spaces not covered by standards.

Step 1: Identify contaminants

- Odors: _____ type

- Chemicals: _____ type

- Moisture: _____ source

- Occupancy: _____ people/hour

Step 2: Research removal rate

- Odor removal: Typically 3–6 ACH

- Chemical removal: Typically 8–15 ACH

- Moisture removal: Typically 4–8 ACH

- CO₂ control: Calculate based on occupancy

Step 3: Calculate CO₂-based ventilation

CO₂ removal rate (CFM) = Number of people × 0.019 × (Desired CO₂ – Outdoor CO₂)

Example:

- 10 people in room

- Desired indoor CO₂: 800 ppm

- Outdoor CO₂: 400 ppm

- CFM = 10 × 0.019 × (800 – 400) = 76 CFM

Step 4: Use highest calculated rate

CFM needed = Max of (odor CFM, chemical CFM, moisture CFM, CO₂ CFM)

ASHRAE 62.1 Ventilation Standards

Overview of ASHRAE 62.1-2022

ASHRAE 62.1 is the industry standard for ventilation and indoor air quality in commercial buildings. The standard has evolved significantly, with the 2022 version introducing stricter requirements for health and energy efficiency.

Key Changes in ASHRAE 62.1-2022

| Change | Impact | CFM Adjustment |

|---|---|---|

| CO₂ setpoint requirement (1000 ppm) | Demand-controlled ventilation | Can reduce CFM by 20–30% |

| Filtration upgrade (MERV 13 minimum) | Better indoor air quality | No CFM change |

| Source separation focus | Reduce pollutant entry | Reduces overall CFM needs |

| Outdoor air quality provisions | Address air quality degradation | May increase CFM in polluted areas |

Ventilation Rate Procedure (VRP)

The Ventilation Rate Procedure calculates required CFM as:CFM=Occupancy (Rp)+Area (Ra)

Where:

- Rp = Outdoor air rate per person (CFM/person)

- Ra = Outdoor air rate per unit area (CFM/100 sq ft)

Common ASHRAE 62.1 Rates (2022)

| Space Type | Rp (CFM/person) | Ra (CFM/100 sq ft) | Notes |

|---|---|---|---|

| Private office | 15 | 0.06 | Based on 7 people/1000 sq ft |

| Open-plan office | 15 | 0.06 | Average occupancy 5–7 people/1000 sq ft |

| Conference room | 15 | 0.06 | Per ASHRAE, treat as office |

| Classroom | 10 | 0.12 | Higher per-area rate for higher occupancy |

| Retail store | 0.30 | 0.30 per sq ft | No per-person component |

| Restaurant (dining) | 7.5 | 0.18 | Moderate activity level |

| Restaurant (bar) | 20 | 0.30 | High activity, alcohol vapors |

| Library | 0 | 0.12 | Minimal occupancy variation |

| Gym/fitness | 20 | 0.12 | High activity, moisture, odors |

| Hotel lobby | 0 | 0.12 | Transient occupancy |

| Hospital patient room | 1 person @ 20 CFM | — | ASHRAE 170, not 62.1 |

Demand-Controlled Ventilation (DCV)

ASHRAE 62.1-2022 encourages CO₂-based demand-controlled ventilation:

- Install CO₂ sensors (typical setpoint: 1000 ppm)

- Modulate ventilation based on occupancy

- Reduces CFM during low-occupancy periods

- Energy savings: 20–40% annually

- Cost: CO₂ sensors + controls = $500–$2,000 per space

Outdoor Air Quality Considerations

New to ASHRAE 62.1-2022:

- If outdoor air quality is poor (AQI > 100), increase filtration rather than CFM

- Use MERV 13+ filters to capture outdoor pollutants

- Acceptable for reducing outdoor air intake in severely polluted areas

Example: In Beijing with frequent AQI > 150:

- Standard: 150 CFM outdoor air

- With MERV 13 + DCV: Can reduce to 100 CFM + increased filtration

- Annual energy savings: 20–30%

ACH and Energy Efficiency

Energy Impact of Ventilation

Ventilation accounts for 15–25% of total HVAC energy in commercial buildings. Higher ACH directly increases:

- Heating energy (conditioning cold outdoor air in winter)

- Cooling energy (conditioning warm outdoor air in summer)

- Fan energy (moving larger volumes of air)

Energy Recovery Strategies to Reduce ACH Penalty

1. Heat Recovery Ventilation (HRV) / Energy Recovery Ventilation (ERV)

How it works:

- Captures heat from exhaust air before it exits

- Transfers heat to incoming fresh air

- Reduces conditioning load on HVAC system

Efficiency:

- HRV (heating climates): 70–90% heat recovery

- ERV (humid climates): 60–80% heat + moisture recovery

Cost-benefit:

- Additional cost: $2,000–$5,000 per 500 CFM unit

- Energy savings: $300–$600/year

- Payback period: 3–8 years

Example: Office with 300 CFM minimum ventilation

- Without HRV: 300 CFM × 0.8 kW/ton = 240W fan energy + conditioning load

- With ERV: 300 CFM × 0.8 kW/ton × 0.75 (recovery efficiency) = 180W + reduced conditioning

- Annual savings at $0.12/kWh: ~$600–$900

2. Demand-Controlled Ventilation (DCV)

How it works:

- CO₂ sensors monitor occupancy

- Ventilation modulates based on actual occupancy

- Reduces CFM during low-occupancy periods

Typical Schedule:

- Peak occupancy: 100% designed CFM

- Medium occupancy: 70% CFM

- Low occupancy: 40% CFM

- Unoccupied: 20% CFM (minimum ventilation)

Energy savings:

- Average annual reduction: 20–40% ventilation energy

- Cost: $1,000–$3,000 for sensors + controls per space

Example: School classroom

- Scheduled ventilation: 300 CFM all day

- DCV ventilation: 300 CFM (class), 100 CFM (empty)

- Average annual CFM: 60% of peak (200 CFM)

- Energy savings: 40% annually

3. Enthalpy Recovery Wheels

How it works:

- Rotating wheel absorbs heat/moisture from exhaust air

- Transfers to incoming fresh air

- More efficient than plate-frame HRV

Efficiency:

- 65–85% sensible effectiveness

- 50–70% latent effectiveness (moisture)

Cost:

- $3,000–$8,000 per 500 CFM unit

- More expensive than HRV but higher efficiency

Best for: Hot-humid climates where moisture recovery valuable

4. Waterside/Airside Economizers

How it works:

- Use cold outdoor air to supplement cooling during mild weather

- Reduces chiller runtime

- Increases ventilation during economizer operation

Free cooling potential:

- Mild climate (spring/fall): 50–70% hours can use free cooling

- Cool climate: 60–80% hours available

- Hot climate: 10–30% hours available

Energy savings:

- Can reduce cooling energy by 30–50% annually

Common Mistakes in ACH Calculations

Mistake 1: Using Average ACH for Mixed-Use Spaces

Wrong approach:

- Space has classrooms (5 ACH) and corridors (2 ACH)

- Average: (5 + 2) ÷ 2 = 3.5 ACH

- Design all spaces for 3.5 ACH

Why it’s wrong: Classrooms need 5 ACH minimum; corridors will be over-ventilated (wasted energy)

Correct approach:

- Design each space to its code requirement

- Classrooms: 5 ACH

- Corridors: 2 ACH

- Total CFM = sum of individual CFM requirements

Mistake 2: Forgetting to Add Outdoor Air Intake

Wrong approach:

- Recirculated air: 500 CFM

- Design assumes all return air is outdoor air

Why it’s wrong: Return air includes recirculated air; only portion is fresh outdoor air

Correct approach:

- Total return air: 500 CFM

- Outside air intake (OA): 150 CFM (calculated per ASHRAE 62.1)

- Recirculated air: 350 CFM

- Design ventilation system for 150 CFM OA + 350 CFM recirculated

Mistake 3: Not Accounting for Duct Leakage

Wrong approach:

- Design CFM: 300 CFM

- Install fan rated 300 CFM

- Actually delivers 270 CFM (10% duct leakage)

Why it’s wrong: System under-delivers due to duct leakage losses

Correct approach:

- Design CFM: 300 CFM

- Account for duct leakage: 300 ÷ 0.90 = 333 CFM design fan size

- Install fan rated 333 CFM to deliver 300 CFM actual

Standard leakage factors:

- Well-sealed ducts (taped seams): 5% loss

- Average ducts (some sealing): 10% loss

- Poorly sealed ducts: 15–20% loss

Mistake 4: Ignoring Ceiling Height Variation

Wrong approach:

- Room floor area: 500 sq ft

- Assume ceiling height: 10 ft

- Volume = 500 × 10 = 5,000 cu ft

- But room has sloped ceiling (8–12 ft range)

Why it’s wrong: Actual volume may be 4,600–5,400 cu ft

Correct approach:

- Measure actual ceiling heights at multiple points

- Calculate volume accounting for slope: (Low height + High height) ÷ 2 × Area

- For 8–12 ft slope: (8 + 12) ÷ 2 = 10 ft average (happens to match assumption, but verify!)

Mistake 5: Over-Relying on Manufacturer’s CFM Ratings

Wrong approach:

- Fan specification sheet: 500 CFM at 0.5 inches water column

- Install fan and assume 500 CFM delivered

Why it’s wrong: Actual ductwork static pressure may be 1.0 inches; at this pressure, fan delivers only 350 CFM

Correct approach:

- Calculate system static pressure (ductwork + filters + coils + dampers)

- Select fan at operating pressure, not at 0.5 inches

- Verify delivered CFM with anemometer after commissioning

Mistake 6: Miscalculating Occupancy for ASHRAE 62.1

Wrong approach:

- Office space: 2,000 sq ft

- Assume 2 people per 100 sq ft = 40 people

- Per person rate: 15 CFM/person

- CFM = 40 × 15 = 600 CFM

Why it’s wrong: ASHRAE 62.1 rates are already based on average occupancy; shouldn’t multiply peak occupancy × per-person rate if using area rate

Correct approach:

- Use either per-person + per-area method together:

- Per person: 10 typical occupants × 15 = 150 CFM

- Per area: 2,000 × 0.06 = 120 CFM

- Total: 150 + 120 = 270 CFM (not 600)

- Or use per-area only:

- 2,000 × 0.06 = 120 CFM (simplified, assumes average occupancy)

Mistake 7: Not Adjusting for Altitude

Wrong approach:

- Design CFM: 300 CFM at sea level

- Install same fan at 5,000 ft elevation

- Assumes same performance

Why it’s wrong: Lower air density at altitude reduces fan performance

Correct approach:

- At 5,000 ft altitude: Air density = 84.5% of sea level

- Design CFM: 300 ÷ 0.845 = 355 CFM fan size needed

- Alternatively: Select fan and derate performance by 15.5%

Altitude corrections:

- Sea level (0 ft): 100%

- 2,000 ft: 93%

- 5,000 ft: 85%

- 7,500 ft: 77%

- 10,000 ft: 69%

Tools & Software for ACH Calculations

Free Tools

| Tool | Best For | Cost | Web-Based |

|---|---|---|---|

| ASHRAE 62.1 Calculator (online) | Commercial buildings, ASHRAE 62.1 | Free | Yes |

| ENERGY STAR Portfolio Manager | Large buildings, utility tracking | Free | Yes |

| EnergyPlus (DOE) | Building energy simulation | Free | No |

| OpenStudio | Advanced HVAC modeling | Free | No |

| Excel Spreadsheets (downloadable) | Custom calculations | Free | No (local) |

Paid Software

| Software | Cost | Features | Best For |

|---|---|---|---|

| Trane TRACE 700 | $2,000–$5,000 | Advanced HVAC design, energy modeling | Commercial HVAC design |

| Carrier AirES | $1,500–$3,500 | Equipment selection, ductwork design | Large commercial projects |

| Coolcalc (subscription) | $500/year | Load calculations, CFM design | HVAC contractors |

| Hourly Analysis Program (HAP) | $3,000+ | Detailed thermal load analysis | Mechanical design firms |

| WATSCO (WorkManager) | Free–$200/mo | HVAC software suite | Contractors, distributors |

| Revit MEP | $500/year (subscription) | BIM coordination, ductwork layout | Engineering design firms |

| AutoCAD MEP | $680/year | MEP coordination, duct sizing | Design & engineering |

Recommended Setup for Famcod Users

Budget Option:

- Excel spreadsheet (free) + ASHRAE 62.1 calculator (free)

- Total: $0

- Time to learn: 2–4 hours

Mid-Range Option:

- Trane TRACE 700 trial ($0 trial, $2,500 full)

- ENERGY STAR Portfolio Manager (free)

- Total: $2,500

- Time to learn: 40+ hours

Professional Option:

- Carrier AirES + Revit MEP + Primavera (if you do scheduling)

- Total: $5,000–$8,000/year

- ROI: High for design firms

Case Studies & Real-World Examples

Case Study 1: Office Retrofit with DCV Implementation

Project: 50,000 sq ft office building, Chicago

Original Condition:

- Fixed ventilation: 500 CFM minimum outdoor air (24/7)

- Average occupancy: 40% during business hours

- Annual HVAC energy: $45,000

Problem: Over-ventilation during low-occupancy periods wasting energy

Solution Implemented:

- Added CO₂ sensors in 30 zones

- Programmed DDC system for demand-controlled ventilation:

- 8 AM–6 PM (occupied): 500 CFM (100%)

- 6 PM–8 AM (unoccupied): 150 CFM (30%)

- Cost: $25,000 (sensors + controls)

Results (Year 1):

- Average ventilation CFM: 350 CFM (vs. 500 previously)

- Annual HVAC energy: $31,500 (30% reduction)

- Annual savings: $13,500

- Payback period: 1.85 years

- Improved IAQ: Employee surveys showed 15% improvement in air quality perception

Lesson Learned: DCV is highly cost-effective for buildings with variable occupancy

Case Study 2: Hospital Operating Room ACH Upgrade

Project: 8 operating rooms, Boston hospital

Original Condition:

- Operating rooms: 10 ACH (outdated standard)

- Infection rate: 2.3% surgical site infections

- Annual HVAC cost: $120,000

Problem: Infection control improvements required, ACH inadequate

Solution Implemented:

- Upgraded to 15 ACH (ASHRAE 170-2017 standard)

- Installed 3-stage filtration (MERV 13 + HEPA + ULPA)

- Added positive pressure control

- Cost: $180,000 (ductwork upgrade + new fans + filters)

Results (Year 1):

- Surgical site infection rate: 0.8% (65% reduction)

- Annual HVAC cost: $156,000 (30% increase from higher CFM)

- Infection prevention savings: ~$500,000 annually (fewer complications, shorter stays)

- ROI: Extremely positive (medical outcomes far exceed energy costs)

Lesson Learned: In healthcare, IAQ improvements justify higher energy costs

Case Study 3: School Classroom ACH Standardization

Project: 45-classroom K–8 school, California

Original Condition:

- Classrooms built in 1980s: ~2 ACH

- CO₂ levels frequently exceeded 1,500 ppm

- Student test scores: Average 45th percentile (county average)

Problem: Low ventilation affecting student cognitive performance

Solution Implemented:

- Increased minimum ACH from 2 to 4 in all classrooms

- Added ERV system for energy recovery

- Implemented CO₂ monitoring

- Cost: $280,000 (ductwork + HRV unit + controls)

Results (Year 2):

- CO₂ levels: Consistently under 800 ppm

- Student attendance: +2.3% (fewer sick days)

- Test scores: Improved to 54th percentile (9-percentile improvement)

- Annual energy increase: $8,500

- Annual energy savings (ERV): $6,200

- Net annual cost: $2,300

- Teacher feedback: Improved focus & alertness noticed

Lesson Learned: Educational performance improvements can offset ventilation energy costs

Frequently Asked Questions (FAQ)

Q1: What is the difference between ACH and CFM?

A:

- CFM = Absolute ventilation rate (cubic feet per minute)

- ACH = Relative ventilation rate normalized to room volume

Example: A 1,000 cu ft room with 100 CFM = 6 ACH; a 2,000 cu ft room with 100 CFM = 3 ACH. Same CFM, different ACH.

Q2: Can I have too much ventilation (too high ACH)?

A: Yes. Excessive ventilation causes:

- Energy waste: Unnecessary conditioning of outdoor air

- Drafts: Uncomfortable air movement

- Noise: Higher fan speeds

- Dry air: In cold climates, excessive outdoor air dries indoor air

- Cost: Increased operating expenses

Optimal ACH balances IAQ with energy efficiency.

Q3: How do I know if my ventilation is adequate?

A: Measure actual ACH with tracer gas:

- Release tracer gas (sulfur hexafluoride SF6) into room

- Measure concentration decay over time

- Calculate decay rate to determine actual ACH

- Compare to design ACH

Cost: $500–$1,500 for professional testing

Q4: Does ACH affect heating/cooling costs significantly?

A: Yes, substantially. Increasing ACH from 2 to 4:

- Winter: 15–25% increase in heating energy

- Summer: 20–30% increase in cooling energy

- Annual: $2,000–$5,000 additional cost per 5,000 sq ft space (depending on climate)

Energy recovery can offset 40–60% of this penalty.

Q5: What is a reasonable ACH for a typical home?

A:

- New construction: 0.6–1.2 ACH (ASHRAE 62.2 compliance)

- Average home: 1–2 ACH

- Leaky old home: 3–5 ACH

- Excessively tight home: <0.5 ACH (may need mechanical ventilation)

Most homes benefit from 1–2 ACH for health without excessive energy use.

Q6: Should I use natural ventilation or mechanical ventilation?

A:

- Natural ventilation (windows): 0.5–2 ACH

- Pros: No energy cost, easy

- Cons: Variable, weather-dependent, security/noise issues

- Mechanical ventilation (HVAC): 2–6 ACH

- Pros: Controllable, consistent, can add heat recovery

- Cons: Energy cost, maintenance required

Hybrid approach: Natural ventilation (windows) for mild weather + mechanical for extreme temperatures = best of both.

Q7: How does outdoor air quality affect ACH requirements?

A: In polluted areas:

- Poor outdoor air (AQI > 100): May reduce ACH, increase filtration instead

- Moderate outdoor air (AQI 50–100): Standard ACH with MERV 13 filters

- Clean outdoor air (AQI < 50): Standard ACH, basic filtration adequate

Example: Beijing’s wintertime smog (AQI 300+) may warrant reducing outdoor air intake from 200 CFM to 100 CFM, with MERV 13 + activated carbon filtration.

Recommended Learning Resources

Books

Online Courses

Tools & Calculators

- ASHRAE 62.1 Simplified Calculator (Free online)

- Quick CFM calculations for ASHRAE 62.1 compliance

- Website: ashrae.org

- HVAC Load Calculation Spreadsheet (Excel, Free download)

- Comprehensive ACH + load calculation tool

- Available: HVAC forums, ASHRAE website

- CO₂-Based Ventilation Calculator

- Design ventilation based on CO₂ setpoints

- Cost: Free on many HVAC sites

Standards & References

Conclusion

Air Changes per Hour (ACH) is a foundational concept for HVAC designers, facility managers, and building professionals. Mastering ACH calculations ensures:

✅ Healthy indoor environments (adequate IAQ)

✅ Code compliance (ASHRAE 62.1, 62.2, local codes)

✅ Energy efficiency (optimized ventilation, reduced waste)

✅ Occupant comfort (appropriate temperature, humidity, air quality)

Whether you’re designing a residential home, commercial office, or specialized healthcare facility, the principles and formulas in this guide will help you specify ventilation systems that balance all four objectives.

Key Takeaways

- ACH formula: CFM = (ACH × Volume) ÷ 60

- Standards vary by building type: Homes (0.6–1.2 ACH), offices (2–4 ACH), hospitals (6–15 ACH)

- ASHRAE 62.1 is the industry standard for commercial buildings

- Energy recovery (HRV/ERV) reduces ventilation costs by 40–60%

- Demand-controlled ventilation (DCV) saves 20–40% annually through CO₂-based modulation

- Proper design requires accounting for duct leakage, altitude, and space-specific contaminants

Next Steps

- Download the free ACH calculation spreadsheet (Excel template in our Resources section)

- Take the Coursera HVAC Design course for deeper knowledge ($39)

- Use the ASHRAE 62.1 calculator online for your specific project

- Consult a licensed HVAC engineer for code-critical projects (hospitals, schools, restaurants)

- Invest in energy recovery equipment for buildings with high ventilation requirements

Free Resources Available

Download our exclusive Famcod HVAC Resources:

- ACH Calculation Spreadsheet (Excel)

- ASHRAE 62.1 Quick Reference Guide

- Building-Type ACH Requirements Checklist

- Energy Recovery ROI Calculator

- Ventilation System Design Template

Sign up for our email list to get instant access to all resources + weekly HVAC tips.

![HVAC BIBLE [10 in 1] The Ultimate Beginner's Guide: Mastering Res...](https://m.media-amazon.com/images/I/517xGvMqrUL._SL500_.jpg)