Visual illustration of activity duration estimating techniques applied in construction planning and scheduling.

1. Introduction to Activity Duration Estimating

Activity duration estimating is the foundation of every construction schedule. Without accurate duration estimates, even the most sophisticated Critical Path Method (CPM) analysis, resource leveling, and risk mitigation efforts fail. The schedule becomes unrealistic, stakeholders lose confidence, and the project descends into chaos.

In construction, duration estimates determine everything:

- Critical path identification: Which activities control project completion

- Resource allocation: How many crews, how long on site

- Cash flow forecasting: When work completes, when billing occurs

- Risk assessment: Where buffers are needed

- Claims substantiation: Proving delays impacted schedule

Table of Contents

Poor duration estimates cause 90% of schedule variances in construction projects. Consider these real-world consequences:

- Labor costs: 12-day activity estimated at 10 days with 15 workers = $30K overrun

- Equipment rentals: Crane rental for 6 weeks planned, activity extends to 8 weeks = $50K extra

- Material waste: Materials ordered for 4-week phase sit unused for 2 weeks = $15K storage/handling

- Claims exposure: Contractor claims owner delay impacted critical path, but unrealistic baseline discredits claim

This comprehensive guide covers all major activity duration estimating techniques used in construction—from basic analogous methods to sophisticated PERT analysis. You’ll learn practical formulas, productivity benchmarks, real-world examples, and common pitfalls to avoid. Whether managing a $1M renovation or $100M infrastructure project, these techniques ensure your schedules reflect reality, not wishful thinking.

Ready to master construction project management?

Enroll in Coursera: “Project Management in Construction Specialization” by Columbia University. Covers scheduling, cost control, risk management, and execution for real-world projects.

Start Coursera Course Now

2. Why Accurate Duration Estimating Matters in Construction

2.1 Schedule Integrity & Critical Path

Duration estimates define the critical path—the sequence of activities that determines project completion. Underestimate by 20%, and your 12-month project becomes 14.4 months. Overestimate by 20%, and you lose competitive bids.

Example impact:

textOffice building project (120,000 sq ft):

- Framing estimated 8 weeks → actual 12 weeks (50% underestimate)

- Critical path delay: 4 weeks

- Total project slip: 4 weeks

- Cost: $2,500/day × 20 days = $50K liquidated damages

- Plus: Extended overhead, equipment, supervision costs

2.2 Resource Planning & Cost Control

Duration directly drives resource needs:

textDrywall activity:

Scenario 1: 10 days × 4 workers = 320 labor hours

Scenario 2: 15 days × 4 workers = 480 labor hours (+50% cost)

Same scope, different duration → dramatically different costs

Industry data: Labor costs represent 40-60% of total construction costs. Inaccurate duration estimates create massive cost variances.

2.3 Cash Flow & Financing

Construction companies live on progress payments tied to schedule milestones. Slip the schedule, slip the cash:

textMonth 3 milestone: $2.5M billing planned

Actual completion: Week 4 of month 4

Cash shortfall: $2.5M × 4 weeks × 10% carrying cost = $100K lost

Banks monitor schedule performance for construction loans. Slipping milestones triggers covenant violations, increased interest rates, or loan calls.

2.4 Claims & Dispute Resolution

Your baseline schedule becomes evidence in delay claims. Unrealistic durations undermine credibility:

textContractor claims: "Owner's RFI delayed steel delivery 3 weeks"

Owner defense: "Your baseline showed 6 weeks for steel, not 3 weeks"

Result: Claim denied due to unrealistic baseline

Forensic schedule analysis (used in 70% of construction disputes over $5M) relies on credible duration estimates as the foundation.

2.5 Stakeholder Confidence & Project Success

Unrealistic schedules erode trust:

- Owner: “This contractor doesn’t understand the work”

- Subcontractors: “Schedule meaningless; we’ll work when we can”

- Team: “Impossible targets; no one tries”

Realistic schedules build momentum:

- Small wins create confidence

- Team focuses on achievable goals

- Stakeholders celebrate milestones together

3. Fundamental Concepts of Duration Estimation

3.1 What Constitutes “Duration”?

Activity duration includes all time from start to finish, not just productive work hours:

textFraming activity (12 days total):

Day 1: Mobilization, layout (4 hours productive)

Day 2: Material delays (2 hours productive)

Day 3-10: Full productivity (8 hours/day)

Day 11: Weather delay (4 hours productive)

Day 12: Demobilization, cleanup (2 hours productive)

Total labor hours: 68 hours

Calendar duration: 12 days

Productivity factor: 68 ÷ (12 × 8) = 71%

Key concept: Calendar duration ≠ labor hours. Always estimate calendar time.

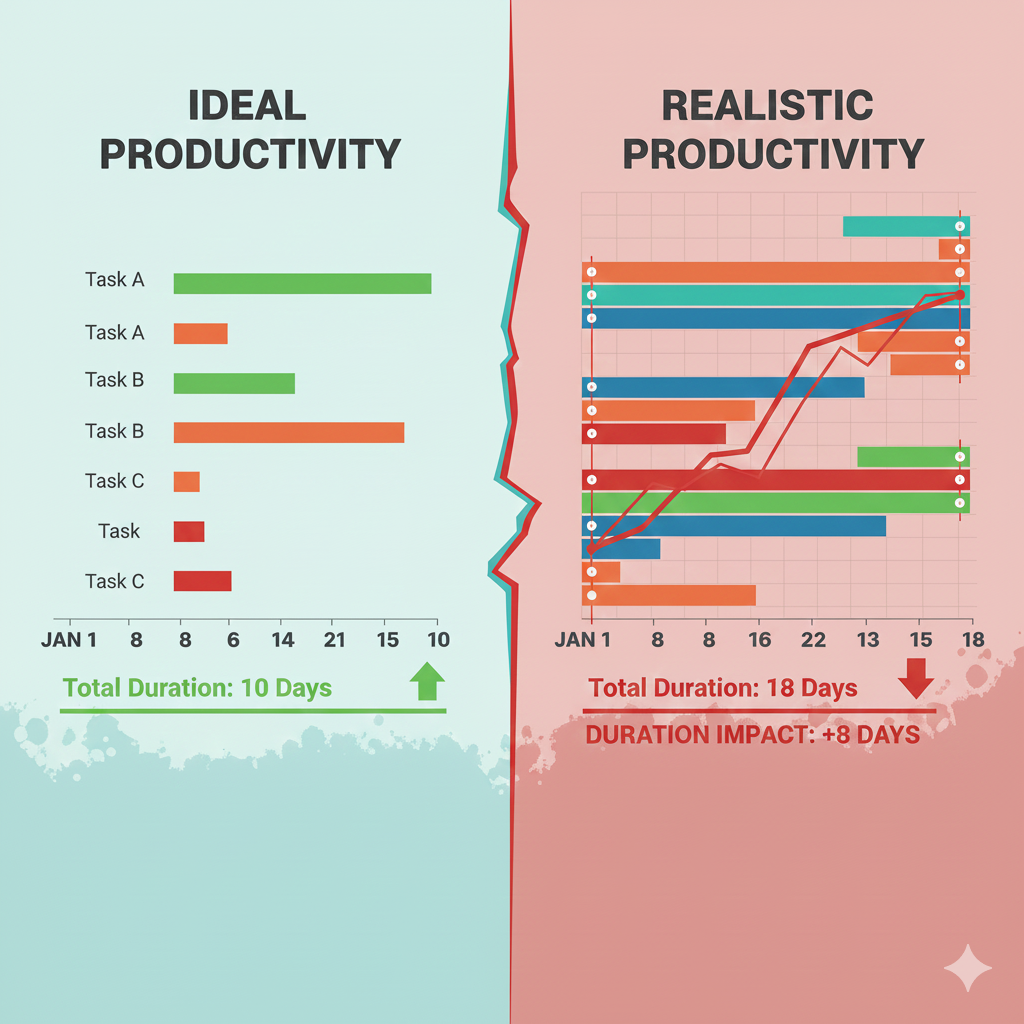

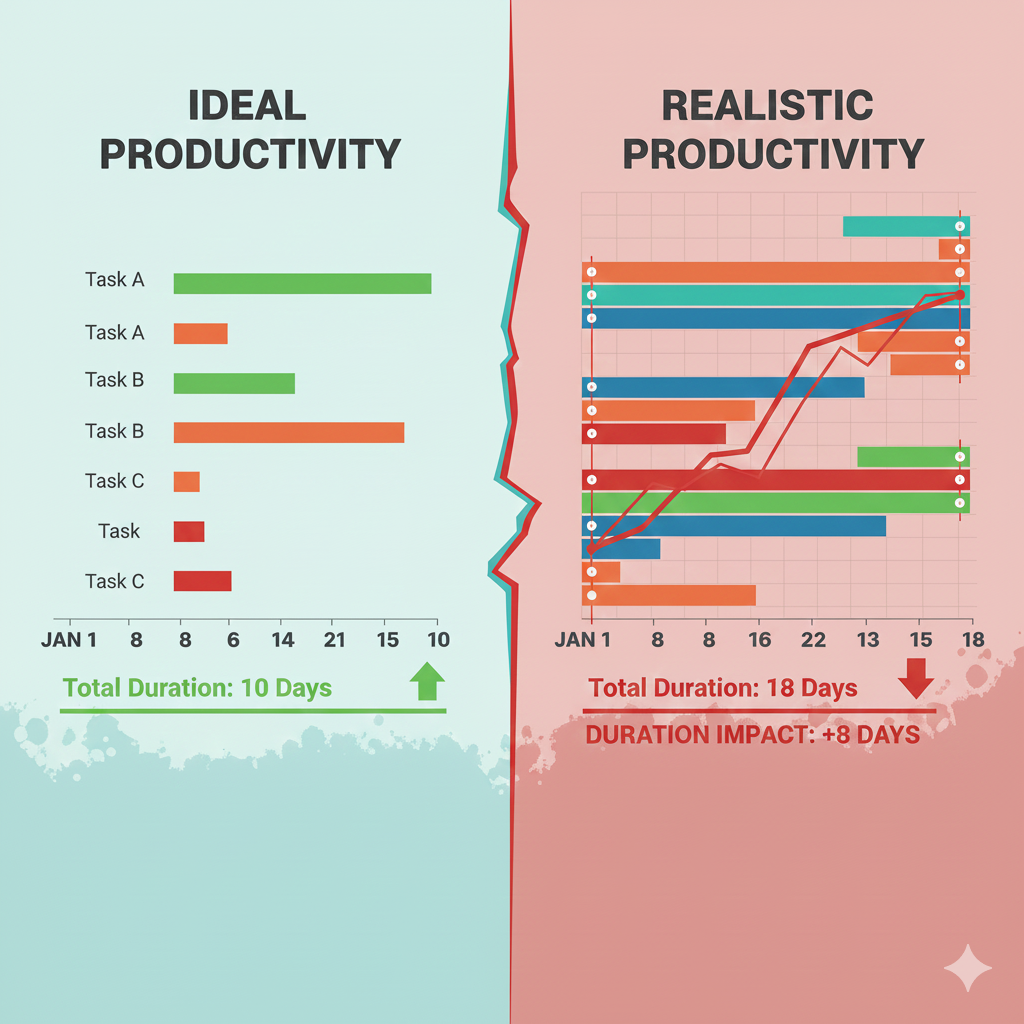

3.2 Productivity Factors

Productivity varies dramatically based on conditions:

textDrywall hanging (ideal vs. real conditions):

Ideal conditions: 1,500 sq ft/day/crew

- Open space, good access, pre-cut materials

Real conditions: 800 sq ft/day/crew

- Mechanical conflicts, tight access, field cutting

Productivity adjustment: 800 ÷ 1,500 = 53%

Duration doubles when using ideal rates

Standard productivity factors:

- Congested site: 70-85% of ideal

- Weather (rain/cold): 60-80% of ideal

- Overtime fatigue: 80-90% of ideal

- Learning curve (first week): 70-85% of steady state

- Night shift: 75-85% of day shift

3.3 Crew Balance & Gang Size

Productivity isn’t linear with crew size:

textConcrete crew productivity:

1 crew (4 workers): 12 cubic yards/day

2 crews (8 workers): 22 cubic yards/day (not 24)

3 crews (12 workers): 28 cubic yards/day (not 36)

Why? Supervision overhead, material handling bottlenecks, coordination losses

Optimal gang size exists for each activity type

- Sold as 1 Each.

- All Grades. Helpful for visual learners, this book dissects sentences so students are better able to grasp the writing c…

- Provides opportunities to segment the parts of sentences for better understanding of the English language.

- Used Book in Good Condition

- Great for teaching and learning print and cursive handwriting

- Double lines help proper letter placement

- Practice cursive connections

4. Analogous Estimating: Historical Data Method

Analogous estimation uses actual durations from similar past projects.

4.1 When to Use Analogous Estimating

Best for:

- Repetitive work (similar building types)

- Early project stages (concept/bid phase)

- Experienced estimators with good historical data

Example projects for analogous:

textPast: 80,000 sq ft office (3 stories)

Current: 100,000 sq ft office (4 stories)

Similar enough for analogous estimation

textPast: Hospital (complex MEP, strict codes)

Current: Office building (standard MEP)

Not similar; analogous unreliable

4.2 Analogous Estimation Process

textStep 1: Identify similar past project

Step 2: Extract relevant activity durations

Step 3: Adjust for scope differences

Step 4: Adjust for condition differences

Step 5: Apply to current project

Example: Structural steel erection

Past project: 40,000 sq ft office, 120 tons steel

- Erection duration: 6 weeks

- Productivity: 120 tons ÷ 30 days = 4 tons/day

Current project: 100,000 sq ft office, 300 tons steel

- Raw estimate: 300 ÷ 4 = 75 days = 15 weeks

- Adjustments:

* Larger project (better crew continuity): -10%

* More complex geometry: +15%

* Experienced crew: -5%

- Net adjustment: +0%

- Final estimate: 15 weeks ✓

4.3 Pros & Cons

| Method | Pros | Cons |

|---|---|---|

| Analogous | Fast; based on real data; good for bids | Limited to similar projects; perpetuates past inefficiencies |

5. Parametric Estimating: Productivity-Based Approach

Parametric uses productivity rates per unit of work (sq ft, tons, linear feet).

5.1 Parametric Formula

Duration (days)=Productivity Rate×Number of CrewsTotal Quantity

Example: Concrete foundation

textQuantity: 1,200 cubic yards

Productivity: 12 cubic yards/day/crew

Crews: 2

Duration = 1,200 ÷ (12 × 2) = 50 days

5.2 Construction Productivity Benchmarks

Industry-standard rates (adjusted for conditions):

| Trade/Activity | Ideal Rate | Average Rate | Poor Conditions |

|---|---|---|---|

| Concrete pour | 15 cy/day/crew | 12 cy/day/crew | 8 cy/day/crew |

| Drywall hanging | 1,500 sf/day/crew | 1,000 sf/day/crew | 600 sf/day/crew |

| Steel erection | 5 tons/day/crew | 4 tons/day/crew | 2.5 tons/day/crew |

| Electrical rough-in | 25 outlets/day/elec | 20 outlets/day/elec | 12 outlets/day/elec |

| Painting | 2,000 sf/day/painter | 1,500 sf/day/painter | 1,000 sf/day/painter |

cy = cubic yards, sf = square feet, elec = electrician

5.3 Crew Size Optimization

textConcrete example:

1 crew: 1,200 cy ÷ 12 cy/day = 100 days

2 crews: 1,200 cy ÷ 24 cy/day = 50 days

3 crews: 1,200 cy ÷ 33 cy/day = 36 days (diminishing returns)

Optimal: 2 crews (best cost/time balance)

6. Bottom-Up Estimating: Detailed Task Analysis

Break work into small components; estimate each; sum totals.

6.1 Bottom-Up Process

textExample: Partition wall (1,000 sf total)

FRAMING (2.9 days):

├─ Layout/marking: 4 hours

├─ Cut plates/studs: 6 hours

├─ Install studs/blocking: 10 hours

└─ Install fixture backing: 3 hours

Total: 23 hours ÷ 8 hr/day = 2.9 days

DRYWALL (3.75 days):

├─ Hanging: 12 hours (2 crew)

├─ Tape/mud coat 1: 6 hours

├─ Tape/mud coat 2: 5 hours

├─ Tape/mud coat 3: 4 hours

└─ Sanding: 3 hours

Total: 30 hours ÷ 8 hr/day = 3.75 days

Total wall duration: 6.65 days (round to 7 days)

6.2 Bottom-Up Checklist

- Include mobilization/demobilization

- Include material handling/unloading

- Include cleanup between activities

- Include rework allowance (5-10%)

- Include inspection/testing time

- Verify crew size appropriate for task

7. PERT Three-Point Estimating: Risk-Adjusted Method

PERT accounts for uncertainty using optimistic, likely, pessimistic estimates.

7.1 PERT Formula

Expected Duration=6O+4L+P

O = Optimistic, L = Likely, P = Pessimistic

Worked Example: Steel Erection

textOptimistic: 6 weeks (perfect weather, no rework)

Likely: 8 weeks (normal conditions)

Pessimistic: 12 weeks (weather delays, bolt misalignment)

Expected = (6 + 4×8 + 12) ÷ 6 = (6 + 32 + 12) ÷ 6 = 8.33 weeks

7.2 Standard Deviation (Risk Measure)

σ=6P−O

textSteel erection: σ = (12 - 6) ÷ 6 = 1 week

68% chance completion within ±1 week of expected

95% chance completion within ±2 weeks of expected

8. Advanced Duration Estimating Techniques

8.1 Learning Curve Effect

Productivity improves with repetition:

textWeek 1: 100 sf/day/crew (learning)

Week 2: 120 sf/day/crew (10% improvement)

Week 3: 130 sf/day/crew (8% improvement)

Week 4+: 140 sf/day/crew (steady state)

Total for 20 days:

Naive: 20 × 140 = 2,800 sf

Learning-adjusted: (5×100 + 5×120 + 5×130 + 5×140) = 2,650 sf

Duration adjustment: +1.1 days (5% longer)

8.2 Weather Adjustment Factors

textOutdoor concrete work (Northern climate):

Summer (Jun-Aug): 100% productivity

Spring/Fall (Mar-May, Sep-Nov): 85% productivity

Winter (Dec-Feb): 60% productivity

Annual adjustment: (3×100 + 6×85 + 3×60) ÷ 12 = 84% of ideal

Duration increase: 1 ÷ 0.84 = 1.19× (19% longer)

9. Construction Productivity Rates & Benchmarks

9.1 Trade-Specific Benchmarks

| Trade | Activity | Ideal Rate | Typical Rate | Poor Conditions |

|---|---|---|---|---|

| Concrete | Formwork | 200 sf/day/crew | 150 sf/day/crew | 100 sf/day/crew |

| Concrete | Rebar | 2 tons/day/crew | 1.5 tons/day/crew | 1 ton/day/crew |

| Steel | Erection | 5 tons/day/crew | 4 tons/day/crew | 2.5 tons/day/crew |

| Carpentry | Framing | 400 sf/day/crew | 300 sf/day/crew | 200 sf/day/crew |

| Drywall | Hanging | 1,500 sf/day/crew | 1,000 sf/day/crew | 600 sf/day/crew |

| Electrical | Rough-in | 25 outlets/day | 20 outlets/day | 12 outlets/day |

9.2 Regional Productivity Adjustments

textUS Northeast (union labor): 100% baseline

US South (non-union): 110-120% baseline

Middle East (expat labor): 80-90% baseline

India (local labor): 90-110% baseline

10. Tools & Software for Duration Estimation

10.1 RSMeans / Craftsman Books

Industry-standard cost/productivity databases:

- 20,000+ line items with productivity rates

- Regional adjustments

- Crew composition recommendations

- Updated annually

Cost: $500-1,500/year

10.2 Timberline / Sage Estimating

Integrated estimating software:

- Parametric rates built-in

- Historical data tracking

- Automatic duration calculation

- Integrates with scheduling

Cost: $5,000-15,000/year

10.3 Excel Templates

Free/customizable:

textColumns: Activity | Quantity | Unit | Ideal Rate | Adjustment | Actual Rate | Duration

Formulas auto-calculate durations

Simple but effective for small projects

11. Common Mistakes in Duration Estimating

11.1 Using Ideal Productivity Rates

Mistake: Apply lab conditions to real sites

textDrywall: Use 1,500 sf/day → actual 800 sf/day = 88% overrun

Solution: Apply realistic adjustment factors (60-85% of ideal)

11.2 Ignoring Mobilization/Demobilization

Mistake: Only estimate productive work

textFraming: Estimate 10 days → forget 2 days mobilization = 20% short

Solution: Add 10-20% for setup/cleanup

11.3 Linear Crew Scaling

Mistake: Double crew = half time (false)

text2 crews don't always = 2× productivity

Solution: Use tested crew balance data

11.4 No Weather/Seasonal Adjustment

Mistake: Same rates year-round

textWinter concrete: Same speed as summer = disaster

Solution: Seasonal productivity factors

11.5 Single-Point Estimates

Mistake: “It’ll take 10 days” (no risk)

textReality: 8-14 days range

Solution: PERT three-point estimation

12. Case Studies & Real-World Examples

12.1 Case Study: 120,000 sq ft Office Building

Challenge: Bid phase; needed duration estimates in 2 weeks

Approach:

textMethod 1: Analogous (past 80K sf office): Framing 8 weeks

Method 2: Parametric (300 sf/day/crew × 20 crews): Framing 10 weeks

Method 3: Bottom-up (detailed task list): Framing 9.5 weeks

Final estimate: 9.5 weeks (bottom-up verified)

Actual: 9.8 weeks (2.8% variance) ✓ Excellent accuracy

12.2 Case Study: Hospital Expansion (High Complexity)

Challenge: Complex MEP, strict codes, phased occupancy

Approach: PERT three-point

textHVAC installation:

O: 12 weeks, L: 18 weeks, P: 28 weeks

Expected: (12 + 4×18 + 28) ÷ 6 = 19.3 weeks

Actual: 20.1 weeks (4% variance) ✓

Result: Schedule held; no liquidated damages

13. FAQ

Q1: Which estimating method is most accurate?

A: Bottom-up is most accurate for detailed work packages. Use parametric for early bids, analogous for similar projects, PERT for high uncertainty.

Q2: How much contingency should I add to duration estimates?

A: 5-15% depending on risk. Low-risk repetitive work: 5%. Novel/complex work: 15%. Weather-heavy outdoor work: additional 10-20%.

Q3: Should I use ideal or average productivity rates?

A: Average rates (70-85% of ideal). Ideal rates create 20-40% schedule underruns.

Q4: How often should I update duration estimates?

A: Monthly during execution. Compare actual vs. estimated; adjust future estimates based on performance.

Q5: What’s the biggest source of duration estimation error?

A: Ignoring non-productive time (mobilization, weather, coordination, rework). Productive work is only 60-80% of calendar duration.

Q6: Can software replace estimator judgment?

A: No. Software provides benchmarks; experienced estimators adjust for site conditions, crew quality, complexity.

Q7: How do I validate my duration estimates?

A: Cross-check with multiple methods. If analogous, parametric, and bottom-up converge within 10-15%, confidence is high.

Q8: What’s typical framing duration for a 3-story office?

A: 6-10 weeks depending on size (40K-100K sf), crew size, weather. Use parametric: 300 sf/day/crew × 20 crews = ~10 weeks for 100K sf.

14. Conclusion

Activity duration estimating techniques separate successful construction projects from troubled ones. Accurate estimates create realistic schedules that:

✅ Protect profits: Right-size crews, avoid idle time

✅ Build credibility: Schedules that reflect reality gain stakeholder trust

✅ Enable control: Know when delays occur, take corrective action

✅ Support claims: Credible baselines prove entitlement to time extensions

✅ Forecast completion: Realistic visibility into project finish

Key takeaways:

- No single method fits all: Use analogous for bids, parametric for planning, bottom-up for execution, PERT for risk

- Calendar duration ≠ labor hours: Include mobilization, weather, coordination (60-80% productive time typical)

- Productivity is contextual: Adjust ideal rates 60-85% for real conditions

- Validate with multiple methods: Convergence within 10-15% builds confidence

- Update continuously: Monthly actual vs. estimate comparison improves future accuracy

- Document assumptions: Every adjustment must be defensible for claims

Next steps:

- Download free productivity benchmark spreadsheet (link below)

- Benchmark your last 3 projects against industry standards

- Implement PERT for your next high-risk bid

- Join Famcod’s estimating masterclass (Coursera link below)

Master duration estimation, and you’ll master construction scheduling.

Free Resources Available

Download exclusive Famcod estimating resources:

- Construction Productivity Benchmark Spreadsheet (Excel)

- PERT Three-Point Calculator Template

- Duration Estimating Checklist (PDF)

- Crew Balance Optimization Worksheet

Sign up for instant access + weekly construction PM tips.

Related Articles on Famcod

Recommended Resources

Books:

Courses:

- Coursera: “Construction Management Fundamentals Specialization”

University of Maryland course covering parametric and bottom-up methods.

Coursera Affiliate Link - More Construction courses