HVAC preventive maintenance is the foundation of a reliable, efficient heating and cooling system. Most homeowners and facility managers don’t realize that regular maintenance can extend system lifespan by 40% and reduce energy costs by 15-25%. Without a structured preventive maintenance plan, HVAC systems deteriorate gradually, leading to unexpected breakdowns during critical seasons when repair costs skyrocket and technician availability plummets.

This comprehensive guide walks you through every aspect of HVAC preventive maintenance—from understanding your system components to creating a sustainable year-round maintenance schedule. Whether you’re a homeowner protecting your investment or a facility manager overseeing multiple units, this guide provides the practical knowledge to keep your systems running optimally.

Why HVAC Preventive Maintenance Matters

Cost Savings Through Early Detection

Preventive maintenance identifies problems when they’re inexpensive to fix, before they cascade into catastrophic failures. A technician discovering a refrigerant leak during a scheduled maintenance visit might spend $300-600 to recharge the system. The same leak left unchecked will eventually kill your compressor—a $3,000-5,000+ replacement. Similarly, detecting evaporator coil buildup during inspection ($150-300 cleaning) prevents complete system failure ($4,000+ compressor replacement).

The mathematics of preventive maintenance is compelling: two annual maintenance visits averaging $150-200 each ($300-400 total) prevent emergency service calls averaging $800-1,500 and major component replacements costing thousands of dollars. The typical payback period for HVAC preventive maintenance is less than one season.

Extended Equipment Lifespan

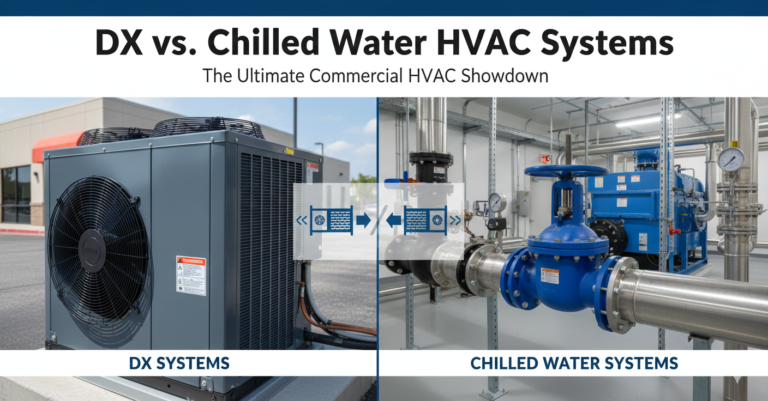

Commercial HVAC equipment is engineered for 15-20 year lifespans under regular maintenance. Systems neglected for years frequently fail at 8-10 years, leaving owners scrambling for emergency replacements. Routine maintenance—refrigerant checks, filter replacement, electrical testing, and component cleaning—keeps mechanical systems within design parameters and prevents accelerated wear.

The compressor, your system’s most expensive component, typically fails prematurely due to inadequate refrigerant charge, contaminated refrigerant, or moisture in the system—all preventable through maintenance. Evaporator and condenser coils coated in dirt and biological growth create excessive pressure and temperature stress on the compressor. Clean coils operating at designed pressures extend compressor life dramatically.

Energy Efficiency Benefits

A well-maintained HVAC system operates at peak efficiency, using minimal energy to maintain comfortable temperatures. Dirty filters force your system to work harder, reducing efficiency by 5-10%. Clogged coils increase compressor head pressure, demanding more electrical input to circulate refrigerant. Ductwork leaks waste conditioned air before it reaches occupied spaces. Worn fan bearings increase friction and energy consumption.

Studies from the U.S. Department of Energy confirm that preventive maintenance maintains HVAC efficiency within 5% of peak performance, while neglected systems degrade to 70-80% efficiency over 5 years. For a typical residential system consuming 3,500-4,500 kWh annually, this efficiency loss translates to $300-500 in additional annual energy costs.

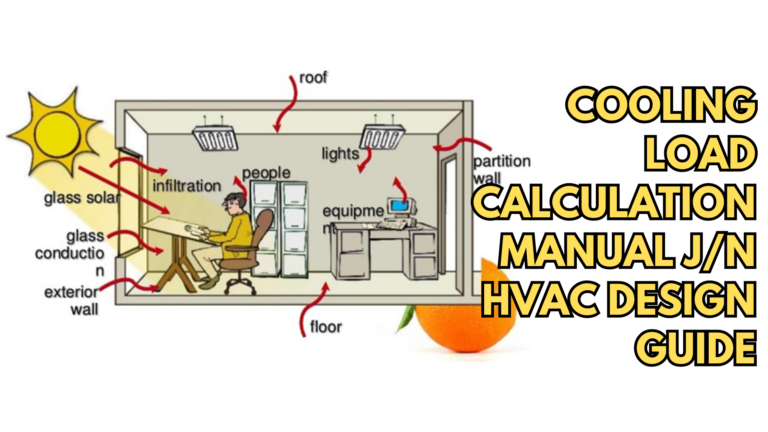

Understanding Your HVAC System Components

Compressor and Refrigerant Lines

The compressor is your HVAC system’s heart, circulating refrigerant through the system to absorb and reject heat. This complex electromechanical component operates under high pressure and stress. The refrigerant lines—two copper tubes connecting indoor and outdoor units—carry pressurized liquid and vapor refrigerant. These lines must maintain precise refrigerant charge and be completely sealed to prevent leaks.

Preventive maintenance protects these components through refrigerant pressure checks, leak inspections, and line cleaning. Technicians measure low-side and high-side pressures, comparing readings to manufacturer specifications. Abnormal pressures indicate leaks, contamination, or system blockage. Identifying and repairing leaks before they deplete refrigerant charge prevents compressor damage.

Air Handlers and Evaporator Coils

The air handler circulates conditioned air throughout your building using a blower fan and motor. Inside the air handler sits the evaporator coil, where cold refrigerant absorbs heat from indoor air. This temperature exchange removes heat and moisture, dehumidifying your space.

Over time, the evaporator coil accumulates dirt, dust, and biological growth (mold, algae). This buildup acts as an insulating layer, reducing heat transfer efficiency and forcing the compressor to work harder. Additionally, biological growth circulates through your ductwork, degrading indoor air quality. Preventive maintenance includes evaporator coil cleaning, typically annually, and sometimes up to twice yearly in humid climates or systems with poor air filtration.

Condenser Units and Outdoor Components

The condenser unit (the outdoor box) houses the condenser coil, where refrigerant rejects heat absorbed from indoor air. A fan pulls outdoor air across the coil to facilitate this heat rejection. These components operate exposed to dirt, pollen, leaves, grass clippings, salt air (coastal regions), and industrial contaminants.

Condenser coil blockage is among the most common HVAC failures. Dirt buildup prevents effective heat rejection, raising refrigerant pressure and forcing the compressor to work harder. Seized fan motors prevent air circulation, causing immediate system failure. Preventive maintenance includes clearing debris around the condenser, cleaning the coil fins with specialized equipment, and inspecting the fan motor for proper operation.

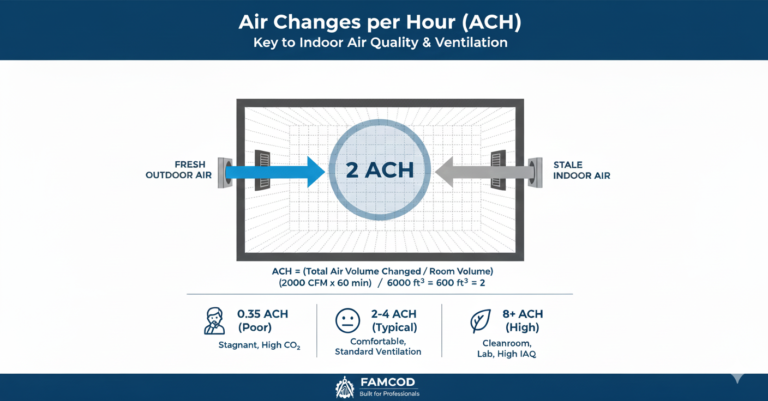

Ductwork and Air Distribution

Ductwork delivers conditioned air to occupied spaces and returns air to the system for reconditioning. Leaky ducts waste 20-30% of conditioned air in unconditioned spaces (attics, crawlspaces, walls), forcing the system to run longer to reach setpoint temperatures. Blocked or collapsed ducts create uneven conditioning and hot/cold spots.

Preventive maintenance includes ductwork inspection for leaks, blockages, and proper insulation. Sealing ductwork can recover 20-30% of energy waste. Cleaning registers, returns, and accessible ducts removes dust and debris that restricts airflow.

HVAC Maintenance Schedule: Seasonal Breakdown

Spring Cooling System Preparation (March-April)

Spring maintenance prepares your system for the cooling season when demand peaks. Schedule an HVAC technician visit in late March or early April, before hot weather arrives and contractors are overwhelmed.

Spring HVAC Maintenance Tasks:

- Replace air filters with new, clean filters (1-inch or 5-inch media filters depending on your system)

- Inspect condenser unit for winter debris—remove leaves, branches, dirt accumulated during dormant months

- Check refrigerant charge by measuring system pressures and comparing to manufacturer specifications

- Test electrical connections on outdoor unit compressor contactor and capacitor

- Inspect condenser fan operation for proper rotation, unusual noise, or vibration

- Verify thermostat operation switching between heating and cooling, proper setpoint control

- Inspect ductwork for visible leaks, separated joints, or blockages

- Verify proper system startup with a full cooling cycle test

Summer Peak Performance Maintenance (June-August)

During summer cooling season, your system runs continuously, placing maximum stress on all components. Mid-summer maintenance (July or August) catches developing issues before they cause peak-season failures.

Summer HVAC Maintenance Tasks:

- Replace air filters again (high-usage months may require 30-day filter changes instead of 90-day)

- Check refrigerant charge monthly if high-usage period extends beyond 30 days

- Inspect condenser coil for dirt, algae, or biological growth and clean if necessary

- Verify adequate airflow by checking ductwork for blockages, register obstructions, or damper position issues

- Monitor system performance for unusual sounds, short cycling, or inadequate cooling

- Clean or replace return air filters if accessible and showing visible dirt

- Inspect for refrigerant leaks at line connections, coil fittings, and valve connections

- Test safety controls including low-pressure cutout switch and high-pressure relief valve

Fall Heating System Readiness (September-October)

Fall maintenance prepares heating systems for winter operation. Schedule service in mid-September to early October, before cold weather arrives and technicians become scarce.

Fall HVAC Maintenance Tasks:

- Replace air filters with fresh filters for the heating season

- Inspect furnace or heat pump for proper operation, unusual sounds, or safety concerns

- Test heating system startup with full operating cycle

- Inspect gas connections and seals (if using gas furnace) for leaks

- Check pilot light or ignition system for proper function

- Verify heat exchanger integrity with visual inspection for cracks or corrosion

- Inspect blower compartment and clean accumulated dust

- Test thermostat heating mode operation and accuracy

- Verify emergency shutoff switches are accessible and functional

- Inspect ductwork insulation in unconditioned spaces to prevent heat loss

Winter System Monitoring (December-February)

Winter operation stresses heating systems continuously. Regular monitoring catches problems quickly when technician availability is limited.

Winter HVAC Maintenance Tasks:

- Replace filters at 30-day intervals during continuous heating operation

- Monitor system performance weekly for unusual sounds, uneven heating, or performance degradation

- Verify adequate outdoor airflow to condenser unit (in heat pump systems) by clearing snow and ice

- Check thermostat operation daily to ensure system maintains setpoint temperature

- Inspect for short cycling (system turning on and off rapidly) indicating possible problems

- Verify humidifier operation (if equipped) to maintain healthy indoor humidity (35-50%)

- Monitor heat pump operation during cold snaps to ensure auxiliary heating activates if needed

Filter Replacement: The Foundation of HVAC Care

Filter Types and MERV Ratings

Air filters trap dust, pollen, pet dander, and other particulates before they circulate through your system. The MERV rating (Minimum Efficiency Reporting Value, 1-16 scale) indicates filtration effectiveness. Higher MERV ratings catch smaller particles but increase airflow restriction.

Common Filter Types:

- MERV 1-4 (Fiberglass): Basic filtration, lowest cost, minimal airflow restriction, traps large particles only

- MERV 5-8 (Pleated): Standard residential filters, good balance of filtration and airflow

- MERV 9-12 (Pleated Media): Enhanced filtration for allergy concerns, moderate airflow restriction

- MERV 13+ (HEPA/Media): Superior filtration for extreme allergen control, significant airflow restriction, may require system modification

Airflow Matters: Using filters with MERV ratings exceeding your system’s design specifications restricts airflow, forcing the blower motor to work harder and potentially reducing system efficiency. Consult your HVAC documentation or ask your technician which MERV rating is appropriate for your specific system.

Replacement Frequency Guidelines

Filter replacement frequency depends on filter type, household conditions, and system usage patterns.

Standard Replacement Schedules:

- Fiberglass filters: Every 30 days (minimum)

- Pleated filters (MERV 5-8): Every 90 days under normal conditions, 30-60 days with pets or allergies

- High-efficiency filters (MERV 9+): Every 60-90 days depending on dust load

Factors Requiring More Frequent Changes:

- Pets in the home (shed hair and dander increase dust load)

- Smoking or other particle-generating activities

- Construction or remodeling projects

- High pollen seasons in your area

- Multiple people in the home

- Chronic respiratory conditions requiring maximum filtration

- Humid climates (humidity promotes mold and biological growth in filters)

Signs Your Filter Needs Immediate Replacement

Check filters visually every 30 days. Immediate replacement indicators include:

- Visible dirt or dust coating: Gray or brown discoloration on filter surface indicates particulate loading

- Airflow restriction: Difficulty seeing light through filter mesh when held to window

- Odors: Musty smell from mold or biological growth

- Performance degradation: System struggling to reach setpoint temperature or humidity control

- Furnace or thermostat error codes: Many modern systems display filter alerts

- Increased energy bills: Restricted airflow forces system to run longer

Professional HVAC Inspections and Tune-ups

What’s Included in Professional Maintenance

Professional maintenance visits include comprehensive system evaluation and performance optimization. A complete HVAC tune-up typically takes 1-2 hours and includes:

Electrical System Testing:

- Voltage and amperage measurements at compressor, blower motor, and condenser fan

- Capacitor testing (capacitors store electrical energy and often fail, preventing component startup)

- Contactor inspection for pitting, corrosion, or improper seating

- Thermostat operation verification in both heating and cooling modes

Refrigerant System Analysis:

- Pressure gauge readings on low-side (suction) and high-side (discharge) lines

- Comparison of measured pressures to manufacturer specifications for your system’s outdoor temperature

- Visual inspection of copper lines for leaks, corrosion, or damage

- Testing of expansion device (TXV or orifice) for proper refrigerant metering

Component Inspection:

- Evaporator coil visual inspection for dirt, ice buildup, or biological growth

- Condenser coil cleaning with specialized equipment if necessary

- Blower wheel inspection for dirt accumulation, proper rotation, and bearing condition

- Condenser fan operation verification for proper rotation and bearing noise

- Compressor sound evaluation for unusual noises indicating potential failure

Safety System Verification:

- Low-pressure cutout switch operation (prevents compressor damage if refrigerant charge is low)

- High-pressure relief valve function (prevents excessive pressure in cooling cycle)

- Flame rollout switch operation (gas furnace safety)

- Limit switch operation (furnace safety during heating)

Refrigerant Checking and Charging

Refrigerant is the “lifeblood” of your HVAC system, absorbing heat indoors and rejecting it outdoors. Unlike water in a car’s cooling system, refrigerant doesn’t deplete—the same refrigerant circulates indefinitely. However, leaks gradually reduce charge, degrading system performance.

A system running low on refrigerant exhibits these symptoms:

- Inadequate cooling or heating despite system running continuously

- Ice forming on evaporator coil (frost accumulation on indoor copper lines)

- High discharge pressure at the condenser unit

- Increased electricity consumption as the system works harder with insufficient refrigerant

Technicians verify refrigerant charge by measuring pressures in both high and low-side lines and comparing readings to temperature-pressure charts provided by the EPA and manufacturers. If charge is low, technicians locate and repair leaks before recharging.

Important Note: Federal regulations (EPA Section 608) strictly prohibit releasing refrigerant into the atmosphere. Only licensed technicians can handle refrigerant, and improper handling results in significant fines.

Electrical Component Testing

Electrical components—capacitors, contactors, fan motors, compressor motors—operate under significant stress and frequently fail.

Capacitor Failures: Capacitors store electrical charge and release it to start motors. A failed capacitor prevents the compressor or condenser fan from starting, killing system operation immediately. Capacitors typically last 5-10 years. Preventive replacement (before failure) prevents emergency service calls.

Contactor Issues: The outdoor contactor is an electromagnetic relay that connects 240-volt line voltage to the compressor when cooling is demanded. Failed contactors prevent compressor startup. Preventive inspection identifies pitting or corrosion that indicates imminent failure.

Motor Bearing Degradation: Blower motors and condenser fan motors operate on ball or sleeve bearings. Worn bearings produce squealing or grinding noises before catastrophic failure. Preventive lubrication (on oil-bearing motors) or bearing replacement (on sealed motors) extends component life.

DIY Preventive Maintenance Tasks vs. Professional Service

| Task | Difficulty | DIY Feasible | Frequency | Cost If DIY | Notes |

|---|---|---|---|---|---|

| Air filter replacement | Very Easy | Yes | 30-90 days | $15-30 | Turn off system, slide old filter out, insert new filter with arrows pointing toward furnace |

| Condenser unit debris removal | Easy | Yes | Monthly (growing season) | Free | Remove leaves, branches, grass clippings around outdoor unit; keep 3-foot clearance |

| Register and return cleaning | Easy | Yes | Quarterly | Free | Vacuum register and return air grilles to remove dust |

| Thermostat battery replacement | Easy | Yes | Annual or when low-battery indicator appears | $5-10 | Replace AA or AAA batteries in thermostat back-up power |

| Ductwork visual inspection | Easy | Yes | Twice yearly | Free | Look for visible holes, leaks at joints, debris |

| Evaporator coil cleaning | Moderate | No | 1-2 times annually | $150-300 | Requires specialized coil cleaning equipment and EPA certification to handle refrigerant lines |

| Refrigerant pressure checking | Moderate | No | Annually (cooling season) | $150-200 | Requires specialized gauges, federal certification (EPA Section 608), leak detection equipment |

| Capacitor testing | Moderate | No | Annually during tune-up | Included in service visit | Improper testing can be dangerous; requires specialized meter and safety knowledge |

| Condenser coil cleaning (chemical) | Moderate | No | 1-2 times annually | $150-300 | Requires commercial-grade cleaner, pressure washing equipment, and system pressure knowledge |

| Complete system tune-up | Complex | No | Twice yearly (spring/fall) | $150-200 per visit | Requires EPA certification, specialized gauges, technical knowledge of refrigeration and electrical systems |

Tasks You Can Handle Yourself

Air Filter Replacement is the single most impactful DIY maintenance task. Locate your furnace or air handler (typically in basement, attic, closet, or garage). Air filters slide into frames on the return side of the system. Note the filter size (common sizes are 16x25x1, 16x25x4, or 20x25x4) and MERV rating, then purchase replacements. Turn off your system, remove the old filter noting the directional arrows, insert the new filter with arrows pointing toward the furnace, and restart the system.

Condenser Unit Maintenance protects your outdoor component. Ensure vegetation is cleared 3-5 feet around the outdoor unit. Remove accumulated leaves, grass clippings, and debris from condenser coil fins. In freezing climates, ensure heat pump condenser units aren’t blocked by snow. Clear the outdoor unit’s air discharge path.

Visual Inspections are critical. Check ductwork for visible leaks, separated connections, or blockages. Look at your air handler and furnace for obvious damage, corrosion, or leaks. Listen for unusual sounds—grinding, squealing, or rattling—during operation.

When to Call a Professional

Refrigerant System Work: Never attempt to add refrigerant yourself. Federal law (EPA 608 Certification) requires licensed technicians. Improper handling damages the environment, violates law, and voids warranties.

Electrical Testing: Capacitors, motors, and contactors operate at 240 volts and can cause serious electrical shock. Testing requires specialized equipment and safety knowledge.

Coil Cleaning: Evaporator and condenser coils require specialized chemical cleaners and high-pressure equipment. Improper cleaning damages delicate coil fins and refrigerant lines.

Compressor Work: If your compressor has failed, only a licensed technician should handle replacement, system evacuation, and recharge. A compressor failure typically means total system replacement ($3,000-8,000+).

Furnace Heat Exchanger Inspection: Gas furnace heat exchangers can develop dangerous cracks causing carbon monoxide leaks. Professional thermal imaging and inspection is essential for safety.

Common HVAC Issues Preventive Maintenance Prevents

Refrigerant Leaks

The Problem: Small refrigerant leaks gradually reduce system charge. As charge depletes, the expansion device (TXV valve) receives insufficient refrigerant to meter properly. System pressures become abnormal. The compressor works harder, consuming more electricity. Evaporator coil temperature drops, causing ice formation and airflow blockage.

Prevention Strategy: Biannual pressure testing identifies charge loss early. Visual inspection of connections, seals, and copper lines reveals external leaks before major damage occurs. Many leaks occur at:

- Compressor discharge and suction service ports

- TXV (thermal expansion valve) inlet and outlet connections

- Evaporator coil inlet and outlet connections

- Access service ports for pressure gauges

Untreated Cost: Refrigerant recharge when leak detected: $300-600. Same leak left untreated until compressor failure: $3,000-5,000+.

Compressor Failure

The Problem: The compressor is your system’s most expensive component ($1,500-3,000 installed). Premature failure results from low refrigerant charge, excessive moisture in the system, or contaminated refrigerant. Running a compressor low on refrigerant is like running an engine without oil—friction destroys internal components.

Prevention Strategy: Maintain proper refrigerant charge through regular pressure testing and leak detection. Sealed system design should never require refrigerant additions. If charge is low, locate and repair the leak. Moisture in the system (from opening lines incorrectly or equipment failure) requires system evacuation, thorough drying, and possible core component replacement.

Untreated Cost: Emergency compressor replacement during peak season: $3,500-7,000+. Compressor replacement combined with system failures: $5,000-10,000+.

Clogged Evaporator Coils

The Problem: The evaporator coil sits in your furnace or air handler, exposed to your home’s circulating air. Dirt, dust, pet dander, and biological growth gradually coat the coil. This buildup acts as insulation, preventing heat transfer. Your system runs longer, consuming more energy, to reach desired temperatures.

Prevention Strategy: Clean air filters prevent most coil buildup. However, coils still require periodic professional cleaning. Ultrasonic or chemical cleaning removes stubborn buildup. In humid climates or homes with poor filtration, biannual coil cleaning prevents mold and microbial growth.

Untreated Cost: Clogged coil causes 10-15% efficiency loss, costing $300-500 annually in excess energy consumption. Severe coil blockage can result in complete system icing and failure requiring emergency service.

Electrical Component Degradation

The Problem: Capacitors, contactors, and motors degrade gradually from thermal cycling, voltage fluctuations, and mechanical stress. A failing capacitor might prevent the condenser fan from spinning. A failed contactor stops the compressor. A worn blower motor bearings create noise and vibration.

Prevention Strategy: Professional electrical testing during maintenance identifies components operating outside specifications. Preventive replacement of capacitors before failure prevents emergency service calls. Most capacitors should be replaced every 5-10 years regardless of apparent condition.

Untreated Cost: Capacitor failure requiring emergency service call: $300-500. Motor failure requiring emergency replacement: $500-1,200. Contactor failure: $200-400.

HVAC Preventive Maintenance Cost Analysis

Annual Maintenance Investment

Typical Annual Preventive Maintenance Costs:

- Spring tune-up visit (1-2 hours): $150-200

- Fall tune-up visit (1-2 hours): $150-200

- Air filters (4-6 filters annually at $15-40 each): $60-240

- Annual total: $360-640

Many contractors offer maintenance agreements bundling biannual visits with priority scheduling, discounts on repairs, and sometimes parts coverage. Annual maintenance agreements typically cost $400-800, with higher-end plans including emergency service discounts or parts warranties.

ROI and Long-term Savings

Return on Investment Calculation:

| Scenario | Cost | Outcome |

|---|---|---|

| Preventive Maintenance Program (10 years) | $3,600-6,400 maintenance | System operates 15-20 years; no major emergencies; energy efficient throughout lifespan |

| No Preventive Maintenance | $0 preventive costs | System fails at 8-10 years; emergency service calls: $4,000-8,000; replacement system: $5,000-10,000; excess energy costs over 10 years: $3,000-5,000 |

| Net Savings | $8,600-13,600 | Preventive maintenance provides massive ROI through extended equipment life and avoided emergencies |

Energy Efficiency Savings: A well-maintained HVAC system operates at 95%+ efficiency. A neglected system degrades to 75-85% efficiency over 5-10 years. For a $1,200 annual cooling/heating budget, efficiency loss costs $180-300 annually—easily covering maintenance costs.

Emergency Repair Costs vs. Prevention

Typical Emergency vs. Preventive Repair Costs:

| Issue | Preventive Cost (Early Detection) | Emergency Cost (System Failed) | Difference |

|---|---|---|---|

| Refrigerant leak | $300-600 (detect/repair leak + recharge) | $3,500-5,000 (compressor replacement) | $2,900-4,400 savings |

| Capacitor failure | $150-300 (replacement during tune-up) | $400-600 (emergency service + replacement) | $100-450 savings |

| Clogged evaporator coil | $150-300 (professional cleaning) | $800-1,500 (emergency service + potential compressor damage) | $500-1,350 savings |

| Condenser fan motor failure | $200-400 (preventive replacement) | $800-1,500 (emergency replacement) | $400-1,100 savings |

A single emergency repair—especially compressor failure—costs more than 5-10 years of preventive maintenance. Emergency service calls (nights, weekends, holidays) often carry 50-100% surcharges over standard pricing.

Frequently Asked Questions About HVAC Maintenance

How often should I service my HVAC system?

Answer: Professional maintenance should occur twice yearly—once before cooling season (March-April) and once before heating season (September-October). Between professional visits, replace filters monthly or every 90 days depending on filter type and home conditions. Perform monthly visual inspections for debris, unusual sounds, or performance changes. During peak usage seasons (summer cooling, winter heating), increase filter replacement frequency to 30-60 days.

What’s included in HVAC preventive maintenance?

Answer: A complete HVAC maintenance visit includes air filter replacement, evaporator and condenser coil inspection (and cleaning if necessary), refrigerant pressure testing, electrical component testing (capacitors, contactors, motors), thermostat operation verification, safety system checks, blower wheel inspection, and ductwork evaluation. The technician performs a full operating cycle test to ensure system is functioning at design specifications. A thorough tune-up typically takes 1-2 hours.

Can I do HVAC maintenance myself?

Answer: Yes, for basic tasks: air filter replacement, debris removal around condenser units, visual inspections, and register cleaning. However, refrigerant system work, electrical testing, coil cleaning, and safety system verification require EPA certification and specialized equipment. Attempting these tasks yourself violates federal regulations and voids warranties. Focus your DIY efforts on air filter replacement (most impactful task) and visual inspections between professional service visits.

How much does HVAC maintenance cost?

Answer: Biannual professional maintenance visits typically cost $150-200 per visit ($300-400 annually). Air filters add $60-240 annually. Many contractors offer maintenance agreements ($400-800 annually) bundling biannual visits with priority scheduling and repair discounts. This preventive investment prevents emergency repairs costing $3,000-10,000+ and extends system lifespan by 5-10 years.

What happens if I don’t maintain my HVAC system?

Answer: Neglected systems experience gradual performance degradation. Energy consumption increases 5-15% annually as components wear. Unexpected failures occur during peak demand seasons (summer heat waves, winter cold snaps) when technician availability is limited and emergency surcharges are highest. System lifespan decreases from 15-20 years to 8-10 years. You face emergency service costs ($800-1,500 per call) and potential major component replacement ($3,000-8,000+). Additionally, indoor air quality suffers from dirty coils and filters, potentially impacting respiratory health.

When should I replace my HVAC system?

Answer: Well-maintained systems typically last 15-20 years. Consider replacement when repairs exceed 50% of replacement cost, or when repair frequency increases dramatically. A system requiring multiple repairs per year signals component wear approaching simultaneous failure. Additionally, older systems (pre-2000) are significantly less efficient than modern units, consuming 20-40% more energy. Energy savings from modern systems often justify replacement even if the old system still operates.

Should I purchase an HVAC maintenance agreement?

Answer: Yes. Maintenance agreements provide excellent value, costing $400-800 annually for biannual visits, priority scheduling, and repair discounts. Compared to $300-400 for occasional tune-ups, the agreement costs slightly more but provides scheduling priority during peak seasons (critical when emergencies are most likely) and often includes parts discounts on repairs. If you want consistent, scheduled maintenance without worrying about timing, agreements eliminate decision paralysis.

How do I know if my HVAC system has a refrigerant leak?

Answer: Symptoms of low refrigerant include inadequate cooling or heating despite continuous operation, ice forming on copper lines around evaporator coil, hissing sounds near connections (escaping refrigerant), high compressor discharge pressure, and increased electricity consumption. However, low refrigerant doesn’t always indicate a leak—improper initial charge or system blockage can also cause symptoms. Only a licensed technician with proper equipment can diagnose the actual cause. Have the system professionally tested if you suspect low refrigerant.

What’s the difference between MERV ratings?

Answer: MERV (Minimum Efficiency Reporting Value) rates filters 1-16 based on their ability to capture particles. MERV 1-4 (fiberglass) capture only large particles and offer minimal airflow resistance. MERV 5-8 (pleated) capture smaller particles and provide standard residential filtration. MERV 9-12 provide enhanced filtration for allergy sufferers. MERV 13+ (HEPA) provide maximum filtration but significantly restrict airflow. Using MERV ratings exceeding your system’s design specifications increases filter clogging and requires the blower to work harder. Choose the highest MERV rating your system can accommodate without airflow restriction (ask your technician).

How can I improve HVAC system efficiency?

Answer: Maintain preventive maintenance schedules—clean filters and coils improve efficiency 5-15%. Seal ductwork to eliminate air leaks wasting 20-30% of conditioned air. Upgrade to a programmable thermostat maintaining setpoint temperatures precisely rather than manual adjustment. Ensure proper insulation in unconditioned spaces (attics, crawlspaces) where ductwork runs. Consider upgrading to a higher-efficiency system (SEER 15+ cooling, AFUE 95%+ heating) if your current system is 10+ years old—modern systems are 20-40% more efficient than older units, often justifying replacement through energy savings alone.

Conclusion & Action Plan

HVAC preventive maintenance is not optional—it’s the foundation of reliable, efficient home comfort. The choice is simple: invest $300-400 annually in professional maintenance and $60-240 in filters, or face emergency repairs costing $3,000-10,000+ and decreased equipment lifespan.

Your immediate action items:

- Schedule a professional tune-up with a licensed HVAC contractor this month. If you haven’t had service in over 6 months, request a comprehensive inspection.

- Replace your air filter immediately if you can’t remember when it was last changed. Note the replacement date on the new filter frame for future reference.

- Create a maintenance calendar marking spring (March-April) and fall (September-October) maintenance dates. Set smartphone reminders 2 weeks before each date to schedule appointment.

- Consider a maintenance agreement if you want guaranteed biannual service, priority scheduling during peak seasons, and repair discounts.

- Establish monthly filter checks on the first of each month. Replace filters when visibly dirty or every 90 days, whichever comes first.

The small investment in preventive maintenance today prevents the large emergency repair bill tomorrow. Systems maintained consistently operate efficiently for 15-20 years, saving thousands in energy costs and emergency repairs while ensuring reliable comfort year-round.