Blower motors are the heart of every forced‑air HVAC system. If the motor is wrong for the job, the system will never deliver the right airflow, no matter how good the rest of the design is. Undersized or mismatched motors cause low CFM, hot and cold spots, high energy bills, noise, and premature failures.

This in‑depth blower motor selection guide explains every parameter you must match—horsepower, RPM, voltage, frame, rotation, capacitor, PSC vs ECM—and walks through a worked example and recommended tools. It is written for HVAC technicians, engineers, advanced DIYers, and facility managers who want to choose the right motor the first time and avoid expensive callbacks.

Table of Contents

What a Blower Motor Actually Does

In a typical furnace or air handler, the blower motor drives a centrifugal fan (blower wheel or squirrel‑cage) that:

- Pulls air through the return grille and filter

- Pushes air across the evaporator or heating coil

- Delivers conditioned air into the supply ducts and rooms

The motor must generate enough torque to keep the blower spinning at the required RPM against the system’s external static pressure (ESP). If the motor is too weak, airflow drops; if it is oversized or mismatched, it wastes power and can overstress the system.

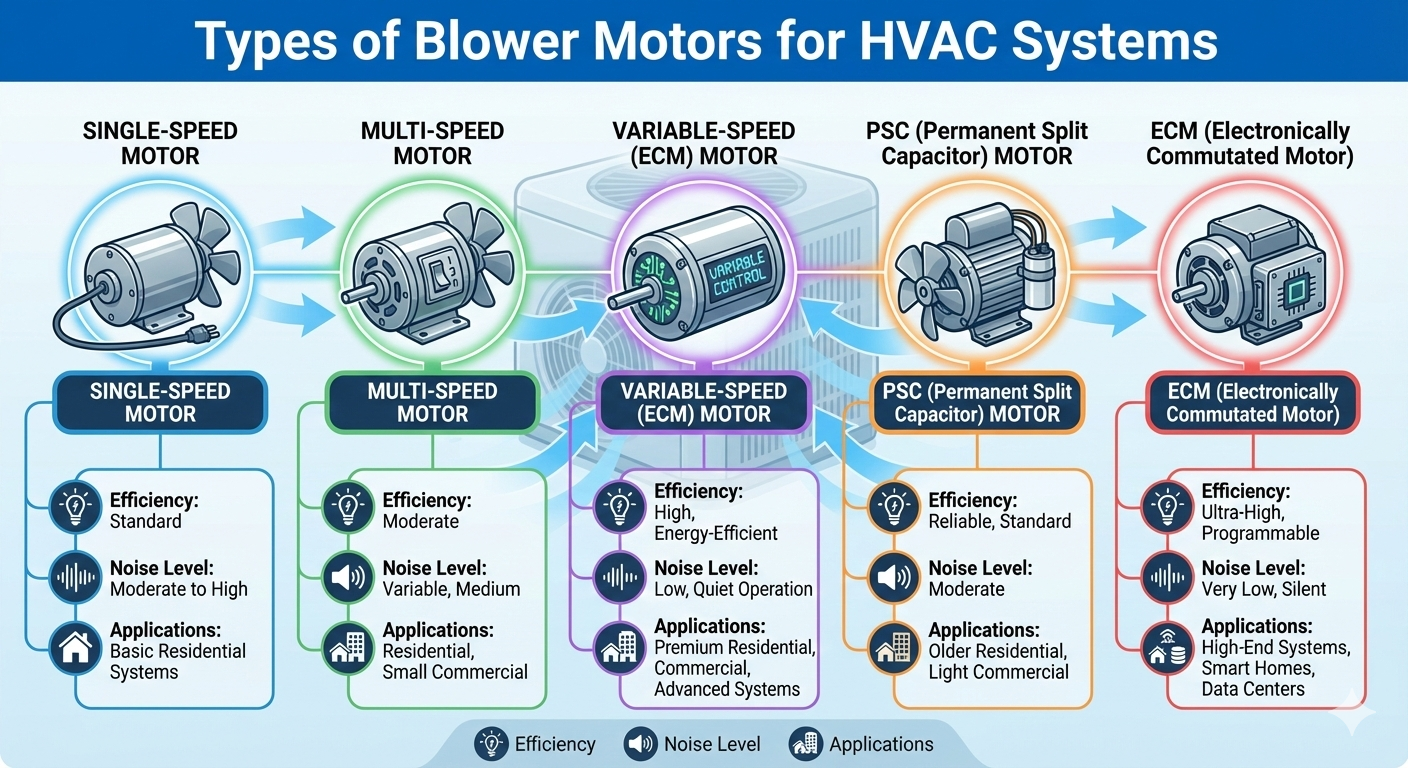

Main Types of Blower Motors

Understanding motor types is the foundation of correct selection.

1. PSC (Permanent Split Capacitor) Motors

These are the traditional workhorse motors in older residential furnaces and air handlers.

- Use a run capacitor to create a phase shift and generate a rotating magnetic field.

- Usually single‑speed or multi‑tap (e.g., low/medium/high speed windings).

- Efficiency typically 60–70%.

- Speed drops significantly as static pressure increases.

- Inexpensive and simple, but not very efficient.

PSC motors are still common in replacement parts for budget systems.

2. ECM (Electronically Commutated Motor)

ECM motors are high‑efficiency brushless DC motors with onboard electronics.

- Use internal electronics and a permanent magnet rotor instead of a capacitor.

- Can maintain nearly constant airflow across a range of static pressures.

- Efficiency often 80–90%.

- Support variable‑speed operation and smooth ramp‑up/ramp‑down.

- Cost more up front but can cut blower energy use by 30–50% and improve comfort.

There are two main ECM categories:

- Constant‑torque / X13: multiple programmed torque steps; commonly used in mid‑range residential units.

- Variable‑speed ECM: true variable airflow control used in high‑end furnaces/air handlers.

3. Shaded‑Pole and Other Specialty Motors

Shaded‑pole and simple split‑phase motors show up in very small fans, bathroom exhausts, and portable units. They’re rarely used for main blower applications and will not be a good replacement for a furnace or air handler blower.

Recommended Course: Design of Ventilation & Air Conditioning System for Buildings Specialization

If you’re looking to deepen your expertise in HVAC design, consider enrolling in the Design of Ventilation & Air Conditioning System for Buildings Specialization .

This comprehensive course covers essential principles, practical design techniques, and real-world applications for building efficient and effective ventilation and air conditioning systems. It’s ideal for engineers, architects, and anyone aiming to advance their career in building services.

Critical Motor Specifications You Must Match

When selecting a replacement blower motor, start from the data plate of the old motor and the air handler, then match or carefully upgrade each of these parameters:

1. Horsepower (HP)

- Common residential blower ratings: 1/6, 1/4, 1/3, 1/2, 3/4, 1 HP.

- HP must be able to overcome system static pressure at the required airflow.

Consequences of wrong HP:

- Too low: motor overheats, trips the breaker, or stalls; poor airflow and coil icing.

- Too high: extra cost and wasted electricity; can overload the blower wheel or be noisy.

Rule of thumb (very rough):

- 1/4 HP: small systems up to ~2 tons

- 1/3 HP: ~2–2.5 tons

- 1/2 HP: ~3–3.5 tons

- 3/4 HP: ~4–5 tons

Always confirm by checking blower performance tables from the equipment manufacturer instead of relying solely on rules of thumb.

2. Voltage and Phase

You must match the supply voltage and phase:

- Typical residential: 115 V or 208–230 V, single‑phase.

- Commercial: may be 208/230/460 V, single or three‑phase.

Using the wrong voltage will overheat or underpower the motor and is unsafe.

3. Full‑Load Amps (FLA)

FLA must be compatible with the circuit breaker and wire gauge. If the new motor draws more amps than the original, you may violate electrical code or trip breakers under load. After installation, always check that measured amps are at or below nameplate FLA.

4. Speed / RPM

Common blower speeds: 825, 1075, 3450 RPM.

- CFM is roughly proportional to RPM: if RPM drops 20%, airflow drops about 20% (all else equal).

- Replacement RPM must match original value unless you also adjust pulley sizes or blower wheel.

If you replace 1075‑RPM motor with 825‑RPM unit without changing anything else, you will significantly lower airflow.

5. Frame Size and Shaft Dimensions

Frame examples: 48 frame, 56 frame.

- Frame defines diameter, mounting hole pattern, and shaft height.

- Shaft diameter (often 1/2″ or 5/8″) and length must fit the blower wheel hub.

If you get frame or shaft wrong, the motor will not physically fit or will misalign and vibrate.

6. Rotation Direction

Many blower motors specify either:

- CW (clockwise) or CCW (counter‑clockwise) rotation viewed from the shaft end.

Some replacement motors are reversible via wiring changes (swapping two specific leads). If direction is wrong, the blower wheel will move far less air.

7. Enclosure Type

- OAO (Open Air Over): cooled by the airstream it’s moving; common in air handlers.

- TEAO (Totally Enclosed Air Over): sealed better for dusty/moist locations.

- TEFC (Totally Enclosed Fan Cooled): own cooling fan; used in harsher commercial environments.

Using an open motor in a dirty or wet space will shorten its life.

8. Mounting Style

- Belly‑band (straps around motor body)

- Resilient base (rubber rings)

- Stud mount (threaded studs at end)

- Foot mount (base feet bolted down)

The new motor must match how the blower assembly is designed to hold it.

9. Capacitor Rating (PSC Motors)

Run capacitors are specified in microfarads (µF) and voltage (e.g., 7.5 µF 370 VAC).

- You must match the µF value specified on the new motor’s nameplate.

- Voltage of replacement capacitor can be equal or higher (e.g., 370 V vs 440 V) but never lower.

- Whenever you replace a PSC motor, plan to replace the capacitor at the same time to avoid callbacks.

10. Ambient Rating and Duty

Check the motor’s maximum ambient temperature (often 40 °C / 104 °F) and duty cycle (continuous). In especially hot mechanical rooms or attics, choose motors with appropriate ambient ratings.

Determining Required Airflow and Motor Size

Correct blower selection is not just matching the old nameplate; it’s ensuring the system can deliver the required CFM against the actual ESP.

1. Calculate Required CFM

- Cooling: typically 400 CFM per ton of cooling for standard comfort systems (sometimes 350–450 depending on design).

- If your cooling load calc indicates 3 tons, target around 1,200 CFM total supply airflow.

Heating CFM can differ depending on furnace temperature rise, but cooling often governs blower sizing.

2. Measure or Estimate External Static Pressure

External static pressure includes:

- Supply and return duct resistance

- Evaporator coil

- Filter

- Registers and grilles

Use a manometer to measure ESP at rated airflow points if possible. For many residential systems, design ESP is around 0.5 in. w.c.; higher values indicate restrictive ducting or filters.

3. Use Manufacturer Blower Tables

Equipment manuals provide tables: CFM vs ESP for each motor HP and speed tap.

- Find the intersection of desired CFM and measured ESP.

- If the existing motor/ tap combination cannot reach target CFM at measured ESP, you must either:

- Reduce ESP by improving ducts/filters, or

- Increase blower HP / change motor type.

Step‑by‑Step Blower Motor Replacement Procedure

Step 1: Document Old Motor and System

- Photograph data plate of the existing motor and control board.

- Note HP, voltage, RPM, FLA, frame, rotation, capacitor size, mounting.

- Record furnace/air handler model number for blower charts.

Step 2: Decide PSC vs ECM

- Same‑type PSC replacement is cheapest and simplest but less efficient.

- ECM upgrade can save energy and improve comfort, especially in systems that run the fan continuously or use variable‑speed control.

For an upgrade, verify:

- Control compatibility (some ECM retrofits use built‑in simple controls; others require specific furnace boards).

- Wheel balance and ductwork can handle higher available static pressure of ECM without excessive noise.

Step 3: Choose the Replacement Motor

Use the following rules:

- Match voltage, phase, and frequency exactly.

- Choose HP equal or one step higher only if blower tables and wiring allow.

- Match frame size, shaft diameter, and length.

- Ensure rotation can be set correctly.

- For PSC: match or exceed capacitor voltage, exactly match µF per motor plate.

- Confirm ambient rating and mounting suit your application.

Step 4: Select the Run Capacitor (PSC Only)

If the new motor needs 10 µF 370 V, buy a new 10 µF 370/440 V capacitor and mount it securely inside the electrical compartment or on a rated bracket. Never reuse a visibly swollen or old capacitor.

Step 5: Installation

- Disconnect power and lock out the breaker.

- Remove blower assembly from the unit.

- Loosen set screw(s) and slide old motor out of the blower wheel.

- Transfer mounting bracket or belly band to the new motor.

- Install motor into wheel with correct insertion depth (wheel centered on housing, blades clear of housing edge).

- Tighten set screw on flat side of shaft if available.

- Reinstall blower assembly in unit.

Step 6: Wiring and Rotation

- Follow wiring diagram from the motor manufacturer.

- For multi‑speed PSC motors: connect appropriate tap (e.g., high speed for cooling, medium for heating).

- For reversible motors: if rotation is wrong, swap the two designated leads.

- Secure all connections with approved connectors and route wires away from moving parts.

Step 7: Commissioning and Verification

After re‑energizing:

- Check amp draw on each leg; it should be at or below nameplate FLA.

- Verify airflow using:

- Temperature rise method (for heating)

- Capture hood/anemometers (for more precise CFM)

- Listen for noise and feel for vibration; correct wheel balance/mounting if necessary.

- Confirm supply temperatures are reasonable and comfort complaints are resolved.

Worked Example: Upgrading a 1/3 HP PSC to 1/2 HP ECM

Situation:

- 3‑ton split system, 1,200 CFM required.

- Original motor: 1/3 HP, 115 V, PSC, 1075 RPM, 48 frame, 5.0 A.

- Static pressure measured: 0.7 in. w.c.

- Blower chart shows 1/3 HP can only deliver ~900 CFM at that ESP.

Problems:

- Complaints of low airflow upstairs.

- Coil freezing on hot days.

- High energy bills.

Solution:

- Install 1/2 HP 115 V ECM constant‑torque blower motor with same frame and shaft size.

- Program ECM tap for 1,200 CFM target.

- At 0.7 in. w.c., new motor maintains ~1,150–1,200 CFM while drawing only ~4.2 A.

Results:

- Comfort improves; upstairs rooms cool properly.

- Coil icing disappears.

- Fan energy drops roughly 30–40%, improving monthly electricity costs.

Recommended Amazon Products (Place Contextually)

Replacement Blower Motors

- 1/3 HP 115V 1075 RPM PSC Blower Motor (48 Frame)

Good like‑for‑like replacement for many small furnaces and air handlers. Reversible rotation, belly‑band mount, includes detailed wiring diagram.

Use when you want a quick, inexpensive swap with existing PSC control. - 1/2 HP 208–230V ECM Constant‑Torque Motor Retrofit Kit

Designed as a direct ECM upgrade for older PSC equipment. Includes pre‑wired harness, mounting hardware, and programming instructions. Suitable for 2.5–3.5 ton systems.

Capacitors and Testers

- Run Capacitor Kit (5–80 µF, 370/440 V)

Handy multi‑value kit covering common blower motor µF ratings. Ideal for technicians servicing multiple systems. - HVAC Clamp Meter with Capacitance Function

Allows you to verify capacitor values, measure motor current, and check voltage safely.

Tools

- Blower Wheel Puller / Hub Puller

Makes removing rusted blower wheels from motor shafts much easier without damage.

Describe each product’s role in the workflow so clicks feel natural and helpful.

Useful Books for Deeper Learning

These book recommendations can also carry affiliate links.

Conclusion

Choosing the right blower motor is much more than grabbing “something close” from a parts shelf. A proper selection process:

- Starts with required airflow and static pressure, not just nameplate horsepower.

- Ensures every specification is compatible—voltage, phase, RPM, frame, shaft, rotation, enclosure, and capacitor.

- Considers whether an ECM upgrade will deliver better airflow, comfort, and energy savings.

- Ends with careful installation, wiring, and commissioning to verify safe operation and correct CFM.

When done correctly, blower motor selection:

- Restores or improves comfort across all rooms

- Reduces breakdowns and nuisance trips

- Lowers fan energy consumption, especially with ECMs

- Protects heat exchangers and coils by maintaining proper airflow

Use this guide as your checklist each time you evaluate or replace a blower motor. Over time, you’ll build a reputation for systems that run quietly, efficiently, and reliably—and you will drastically reduce call‑backs caused by airflow problems.

![HVAC BIBLE [10 in 1] The Ultimate Beginner's Guide: Mastering Res...](https://m.media-amazon.com/images/I/517xGvMqrUL._SL500_.jpg)